As global brands face increasing pressure to go green, we see a rise in “greenwashing”—vague claims where a recycled cardboard box is presented as a total environmental solution. The jewelry industry is no exception.

However, from my perspective on the factory floor at Star Harvest, true sustainability is far more complex and rigorous. It is not a marketing sticker; it is a verified management system. Since our founding in 2005, we have focused exclusively on OEM/ODM manufacturing, avoiding wholesale or retail distractions to dedicate ourselves fully to R&D and production quality.

For brands looking for sustainable jewelry manufacturers, the definition must be strict. It requires a holistic approach that combines ethical governance, material circularity, and technological longevity.

The Foundation: RJC Code of Practice (COP) as the Core System

To identify a truly responsible partner, you must look at their operating system. At Star Harvest, we don’t just follow local rules; we adhere to the Responsible Jewellery Council (RJC) Code of Practice (COP), the global standard for responsible jewelry. We are among the select few fashion jewelry manufacturers to hold RJC, SGS, and ISO certifications simultaneously.

We strictly implemented the RJC COP system starting June 2, 2023. This isn’t a one-time badge we earned; it is a commitment requiring every employee to learn and continuously improve the system’s effectiveness.

According to our COP manual, our sustainability is built on five pillars:

- Environment:We utilize strict environmental policies and risk assessments to prevent accidents.

- Ethics & Supply Chain:We maintain transparent sourcing and management.

- Labor & Health/Safety:We prioritize the protection and well-being of the people who make your jewelry.

Crucially, this system relies on transparency. To avoid the information gaps common in cross-border cooperation, we utilize a comprehensive ERP system for full traceability. Whether it is 3D design files, mold data, plating batch records, or QC reports, every order is traceable to ensure accountability.

The Input: Sustainable Choices via Stainless Steel & Brass

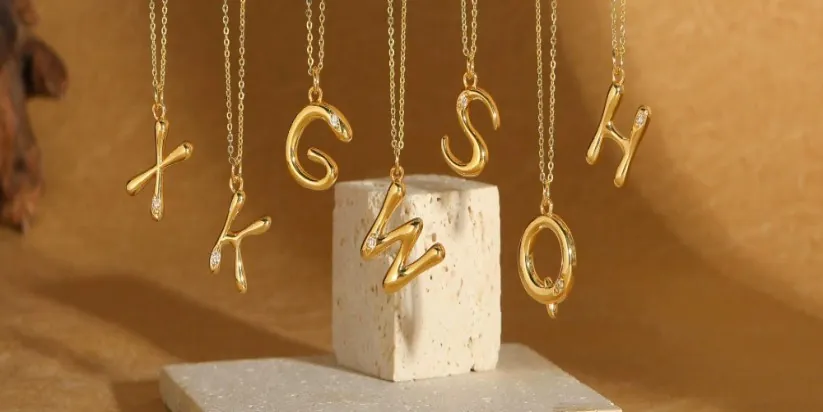

As a premier brass jewelry manufacturer and one of the leading stainless steel jewelry China manufacturers, we view materials through the lens of the RJC environmental ethos: circularity.

The Case for Stainless Steel

We champion stainless steel as a model of the “closed-loop” system. It is 100% recyclable, incredibly durable, and undergoes strict testing to ensure it is free from harmful chemicals. For brands seeking custom stainless steel jewelry manufacturers, this material offers the perfect balance of eco-friendliness and performance.

Responsible Brass Sourcing

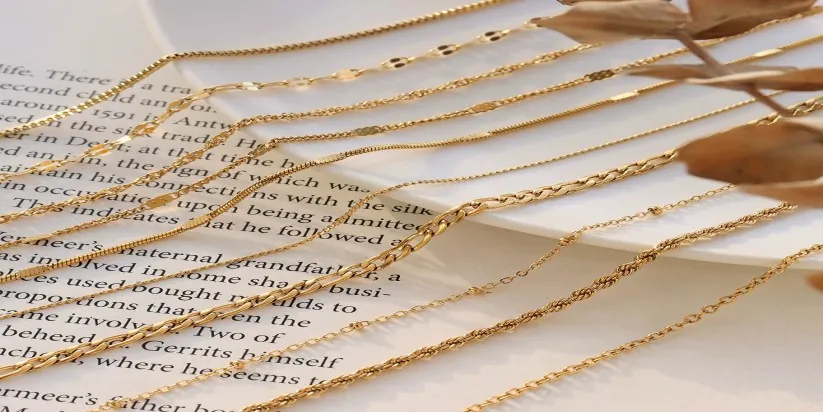

Similarly, brass is a recyclable base metal that aligns perfectly with responsible resource usage principles. We ensure that all raw materials—whether copper or steel—are inspected for integrity and safety before production begins.

To meet the stringent standards of the US and EU markets, we support eco-friendly coatings and low-sensitivity materials. We can rapidly provide material certification reports, such as lead-free compliance, ensuring that your products are non-toxic and market-ready.

The Output: Durability as the Ultimate Sustainability Strategy

There is a philosophy we hold dear at Star Harvest: The most sustainable product is the one that does not need to be replaced.

While using recycled materials is important, extending the lifespan of the jewelry is where true impact happens. This is where our technical expertise distinguishes us from other sustainable jewelry manufacturers.

Innovation: SH-D Patented Technology

To combat the wastefulness of “fast fashion,” we developed our SH-D patented plating technology. Jewelry that resists tarnishing and lasts 2-3 times longer than average, significantly reducing the environmental burden of discarded accessories.

Rigorous Quality Control (SH-P System)

Our commitment to durability is enforced by our SH-P Quality System, where standards are set 30% higher than the industry average.

- Chemical Testing:Every plating batch undergoes thickness and wear resistance tests.

- Longevity Testing:We conduct salt spray tests lasting over 48 hours to ensure color fastness.

- Physical Strength:Chains must survive tensile tests of over 1.5kg.

A Guarantee You Can Trust

We back our quality with a robust service commitment. If any quality or craftsmanship issues arise, we respond within 48 hours with a solution. If the fault lies with us, we take 100% responsibility and can complete rework or replenishment within as little as 3-7 working days.

Conclusion

At Star Harvest, we offer more than just manufacturing; we offer a partnership rooted in verified responsibility. With a monthly capacity of 300,000 to 500,000 pieces and a one-stop service covering design to delivery, we are ready to scale your brand responsibly.

Don’t settle for a manufacturer that simply claims to be green. Partner with Star Harvest, where we strictly implement the RJC Code of Practice to elevate your brand value. Contact us today to discuss your next collection.