In the last decade, I have witnessed a massive shift in the jewelry landscape. PVD stainless steel jewelry is no longer just a budget alternative; it has evolved into the material of choice for modern brands prioritizing durability, price competitiveness, and aesthetic versatility.

However, as the demand for stainless steel grows, so does the variation in quality. I often speak with brand owners who are frustrated because their previous supplier’s gold coating faded within months, or the “gold” color looked unnaturally yellow. The reality is that while Physical Vapor Deposition (PVD) is the industry standard, the execution varies wildly between factories.

The purpose of this guide is to pull back the curtain on manufacturing. I want to equip you with the technical criteria needed to ensure your stainless steel collections meet the high-end standards your customers deserve.

Understanding the Process: Why PVD is Non-Negotiable

To choose the right PVD jewelry manufacturer, you first need to understand why we don’t use traditional methods on stainless steel.

Material Compatibility

In the past, the industry relied on “wet plating” (traditional electroplating). However, standard electroplating struggles to adhere to the dense surface of stainless steel. It sits on top like a sticker, leading to peeling and rapid wear.

The PVD Advantage

PVD is different. It is a vacuum coating process where the coating material bonds at a molecular level with the base metal. This creates superior adhesion compared to standard methods. Because of this vacuum bonding, high-quality golden stainless steel jewelry offers the “holy trinity” of benefits for end-consumers: it is waterproof, sweat-resistant, and hypoallergenic.

Key Criteria for Evaluating PVD Quality

When you are vetting stainless steel jewelry makers, do not just look at the price. You need to ask about the “hard” technical metrics. Here are the three pillars of quality we prioritize at Star Harvest.

1. Color Realism (Solving the “Fake Gold” Issue)

The biggest complaint in the market is PVD coatings that look “fake”—too yellow, too dark, or too brassy. Your customers want the look of solid gold without the price tag.

- The Standard:You must look for a supplier capable of achieving “Real Gold” tones (14k/18k).

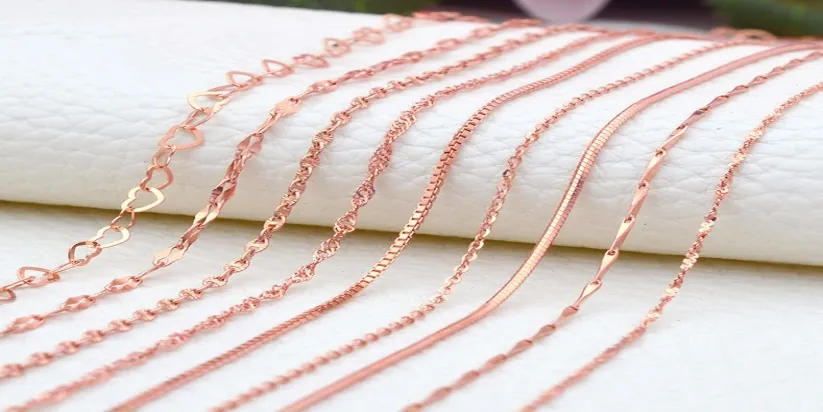

- The Star Harvest Approach:We don’t guess at colors. Our 18K high-saturation warm tone coating is calibrated to precisely match the Pantone 18-1345 luxury color standard. For 14K pieces, we have optimized the red copper ratio to ensure a natural, elegant finish. With over 90 surface finishes available—including custom Rose Gold, Platinum, Gun Metal, and Champagne Gold—we ensure your product looks like luxury.

2. Coating Consistency

A nightmare for any growing brand is receiving a restock order where the gold color is slightly different from the previous batch.

- The Metric:Ask your manufacturer about their color fidelity rates.

- The Star Harvest Approach:Through our tech-driven process, we achieve 99.8% color fidelity across batches. This ensures that the bracelet a customer buys today matches the necklace they buy from you next year.

3. Durability and Thickness Standards

How long will the jewelry last? This is determined by the thickness of the coating, measured in microns (μm).

- The Metric:High-quality PVD should withstand daily wear for years, not months.

- The Star Harvest Approach:We offer fully customizable thickness from 0.1 to 5.0μm.

- Recommendation:For a balance of luxury quality and cost, we recommend a thickness of 1.5-2.0μm. Our data shows this achieves a 3-5 year color retention period.

- ROI:Investing in this thickness can reduce your brand’s warranty and replacement costs by approximately 19%.

- Testing:We verify this through rigorous testing. Our products pass 48+ hour salt spray tests, and our Gun Metal PVD (at just 0.5μm) improves scratch resistance by 70%, passing 96-hour salt spray tests.

How Star Harvest Solves the PVD Challenge

We are not just a factory; we are a tech-driven jewelry manufacturer that has completed over 30 industry process innovations. We developed our proprietary SH-D patented technology specifically to address the limitations of standard PVD.

Unmatched Technology

Our 7 plating patents allow us to create a coating structure that is fundamentally stronger than the industry average. Our SH-DD plating standard increases the bonding strength by more than 30%, creating a finish that is visually indistinguishable from solid gold.

Proven Durability

While the industry average might offer coatings that last a season, our process creates a coating 2-3 times more durable than competitors. We support wear test cycles that prove color retention exceeds 3 years. This allows you to sell PVD stainless steel jewelry with confidence, knowing you are building a reputation for quality.

Conclusion

Choosing the right manufacturing partner isn’t just about who can make a design; it’s about finding a partner who has mastered the science of PVD color and adhesion.

At Star Harvest, we have specialized in custom Brass and Stainless Steel production for over 20 years. As an RJC, SGS, and ISO-certified factory, we guarantee a manufacturing process that is responsible, ethical, and trustworthy.