When your designs demand uncompromising metalwork, our 20-year expertise delivers. We transform your copper or stainless steel sketches into meticulously crafted jewelry – precise finishes, structural integrity assured by 300+ QC touchpoints, and adherence to your exact technical specs. Scalable OEM/ODM production in flexible batches (500-50,000+ pcs) ensures seamless global compliance and consistent readiness for market. Partner beyond the supplier: Achieve brand-aligned craftsmanship without compromise.

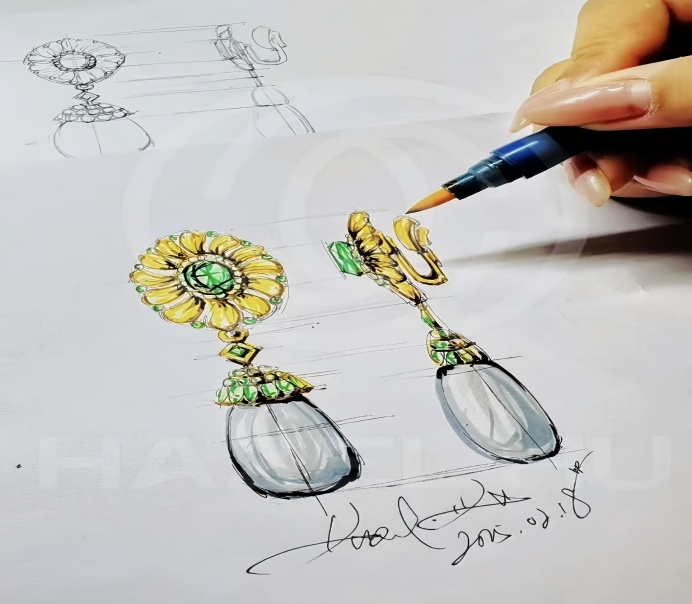

When you have a design concept but struggle to realize it due to limited production resources, Starharvest offers an end-to-end, one-stop custom jewelry production solution to realize your design. Leveraging over 20 years of experience in custom jewelry, we provide comprehensive design development, material optimization, and process optimization. Through rigorous sample verification and quality control, we ensure that each product accurately reflects your design intent.

We support ring precision control from 0.5mm to 10mm, offering customization options for solid, hollow, and adjustable ring configurations. We also develop patented anti-oxidation lining technology for ring boxes, and a hypoallergenic plating layer certified for North American customers (compliant with SGS/REACH standards).

Provides solutions for sensitive earlobes, offering 12 safety structures including screw buckle, magnetic buckle, and silicone ear plug. Supports laser micro-engraving LOGO technology (minimum 0.3mm font).

The entire series comes standard with a break-resistant 7-strand twisted copper-core steel chain (15kg load capacity), with custom chain lengths accurate to ±0.5cm. We also support 3D precision casting of pendants (minimum 0.8cm for complex patterns) and custom development of extension chain accessories.

Patented modular structure allows for free combination of pendant/chain/locking units. New solutions include eco-friendly silicone-lined copper chain (sports style) and magnetic quick-release mechanism.

Luxury-grade titanium steel for men’s wear, precision-carved with a minimum 0.5mm relief precision. Patented non-magnetic base (compatible with medical and aviation applications), supports family crest reproduction and custom development of micro-mechanical transmission structures.

The revolutionary three-point fixed backstitch (anti-twist design) supports multi-material splicing such as enamel, resin, and epoxy. Special application scenarios include: clothing and textile embedded bases, and removable promotional badge components.

We provide professional and flexible OEM customization services, from raw materials to finished products, to ensure that each product meets your market positioning and brand tone. Whether it is a new design and development or an existing product optimization, we can create products with stable quality and reliable delivery according to your needs .

We offer flexible options (such as die casting or lost wax) based on your design drawings, supporting both large and small-volume OEM production, addressing customer pain points such as slow prototyping and high tooling costs. Leveraging 20 years of experience to ensure consistency and tolerance control (±0.1mm accuracy), we can shorten first-sample turnaround time to just 5 days. Whether your e-commerce brand requires complex geometries or minimalist, we can match material parameters (for example, optimizing stainless steel hardness), allowing you to focus on brand design rather than production risks.

We offer custom colors, thicknesses (ranging from 0.5-3μm), and eco-friendly options (compliant with European and American REACH standards), helping you address the challenges of rapid fading and batch-to-batch color variation. Our ODM partnerships allow for rapid color iteration to match brand positioning (e.g., fast color adjustments for popular e-commerce products). Combined with stainless steel or brass substrates, our customizations extend product lifespan and reduce return rates, while also allowing for small-batch orders to test market response.

We can adjust the roughness (Ra value 0.2-1.5μm) to suit your product’s style (such as Nordic minimalist style), addressing customers’ pain point of inconsistent surface quality. Twenty years of expertise ensures batch consistency and avoids secondary processing delays. We support ODM needs for brass or stainless steel jewelry, enhancing tactile comfort and adapting to brand owners’ fast-fashion iterations, shortening your time to market.

We can incorporate your brand elements (such as e-commerce logos or cultural icons) to provide in-depth and fast adjustments, addressing issues such as low pattern accuracy or customization delays. Rapid prototyping and an accuracy of <0.05mm support small-batch OEM trial production. This is ideal for personalized upgrades of brass and stainless steel jewelry, enhancing product storytelling and helping brands stand out from the competition without the risk of excess inventory.

We offer material compatibility (such as heat-resistant stainless steel options) and precise positioning control to address customer pain points such as weak welds and poor batch yields. Our 20-year quality control system ensures a 99% pass rate (IP68 waterproof testing). Our ODM service allows you to specify assembly details (such as weld thickness), ensuring the durability of brass products in high-frequency use and reducing after-sales costs. This service is particularly suitable for the mass production needs of medium and large brands.

We support the matching of sizes and positions of various materials (such as moissanite and rhinestone), addressing issues such as inlay fallout and design limitations. Through modular ODM, we enable rapid prototyping (samples within three days) and accommodate lightweight brass and stainless steel jewelry. This helps e-commerce brands create cost-effective, blockbuster products and increase product premiums without the risk of excessive R&D investment.

Star Harvest’s custom services are designed specifically for brand owners, offering one-stop OEM/ODM solutions for brass and stainless steel jewelry. With 20 years of industry experience, we streamline the customization process, seamlessly bridging the gap from design and development to mass production. We ensure every product meets quality, compliance, and cost-optimization requirements, allowing you to focus on brand building and market expansion.

We offer flexible production solutions. The minimum order quantity for conventional products is 300 pieces. We also support small batch trial orders (minimum order quantity 200 pieces) to verify the process, ensuring zero risk for new customers.

The standard production cycle is 25-35 days. Expedited service is provided during the proofing stage (completed within 7 working days). During the peak period of mass production, an intelligent order scheduling system is used to ensure delivery time.

Implement SH-P multiple quality control system: 1. First piece full size inspection 2. 100% full inspection, equipped with spectrophotometer, hardness tester and other professional equipment to quantify quality control standards.

The entire production process is signed with an NDA confidentiality agreement, and an independent production line is used for closed operation. Once the order is completed, the design files can be delivered to the customer to ensure the security of intellectual property rights.

We provide international test reports in accordance with SGS, LFGB, and other standards to meet REACH and CPSC regulations. We can also provide customized testing for special requirements such as California Proposition 65.

We focus on providing customers with high-quality customized jewelry solutions. Our products cover a variety of materials such as brass and stainless steel to meet the needs of different brands and market positioning. Whether you pursue classic elegance or modern fashion, we can provide a customized solution that perfectly meets your expectations.

We provide a full range of customized jewelry solutions for substrates, including high-quality brass, 304/316L medical stainless steel and other materials, and support the customized development of special alloys. The SH-YF metal pretreatment process can effectively improve the ductility and oxidation resistance of materials. All raw materials are tested for spectroscopy and ductility to ensure compliance with ASTM international standards.

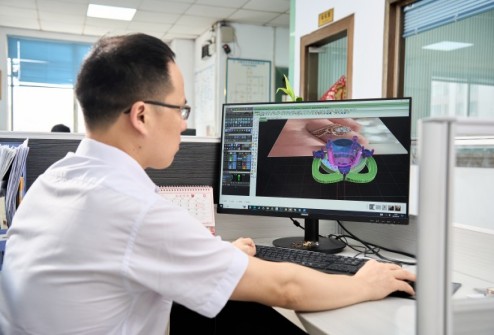

Equipped with CNC engraving center and 3D printing equipment imported from Germany, with an accuracy of up to 0.02 mm , it supports complex processes such as three-dimensional relief and hollow engraving, and provides structural engineering optimization to eliminate production risks. The SH-JM digital modeling system can support rapid proofing of design drafts within 24 hours.

We have established a global supply and procurement network, and can provide customized solutions for more than 2,000 gemstones, including various gemstones and cubic zirconia. We have introduced precision inlay equipment to achieve a micro-inlay accuracy of 0.3mm. Each product has been optically screened to ensure that the color difference of the gemstone is less than 0.5 levels. The SH-XQ firmness test can achieve 300 tensile tests.

Our own electroplating factory is equipped with a variety of electroplating solutions such as vacuum plating and water plating. The nano-level plating is controllable. The SH-DD electroplating standard can increase the electroplating bonding strength by more than 30%. We also provide special process options such as laser plating and gradient plating . We are equipped with a coating thickness gauge for testing.

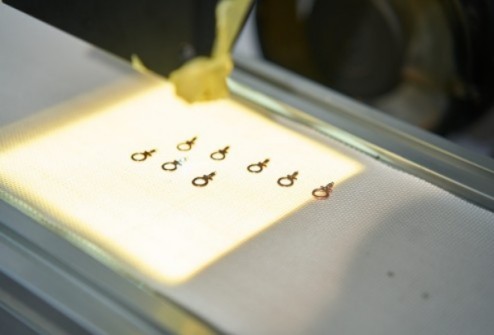

SH Mould Center can quickly develop specific clasps, chains and other jewelry accessories, with a stock of up to 9,000+ that can be called upon at any time. Customized special accessories can be produced and delivered within 7-14 days. And all auxiliary materials have passed the EU nickel release test

For e-commerce customers, making minor adjustments to the original design, such as adding your logo or brand logo, etc. We recommend this solution for customization of name necklace fonts, projection necklace films, etc.