For jewelry innovators demanding true craftsmanship, we transform gemstone visions into meticulously executed reality. Leveraging our 20-year expertise in ethical stone sourcing (natural/synthetic options) and precision gemstone setting technology with 0.1mm tolerance to prevent loosening or damage, we provide jewelry settings for stones at OEM-scale production – sustainably crafting 500-50,000 pieces with exacting consistency for global markets. Join 500+ brands who trust our jewelry settings and gem setting expertise to deliver technically impeccable, legally compliant collections that honor your aesthetic. Start prototyping.

Gemstone customization is an in-depth product creation based on consumer market demand and combined with the brand’s own tone. StarHarvest has over 20 years of experience in jewelry OEM customization, providing full-link manufacturing support from your selected gemstone category (natural/synthetic), cutting shape, to the precision gemstone setting process on the brass/stainless steel base. We offer a variety of jewelry settings for stones such as pave, bezel, and claw, ensuring every gem setting reflects your brand’s aesthetic and every piece benefits from professional jewelry settings craftsmanship.

Customize from a wide library of gemstones , from sapphires to garnets , ensuring your design needs are seamlessly met regardless of market changes .

Available in a variety of shapes, including round and square, they are easily integrated into any jewelry frame, balancing practicality and beauty.

Customize saturation from vibrant to subtle, simplifying color matching and allowing each color palette to perfectly complement your brand story.

We offer flexible sizes from micro-embellishments to main stones, adapting to budgets and market positioning, and enabling cost-effective mass production.

Professional faceting and polishing techniques enhance the expression of light, giving each piece of jewelry a lasting and brilliant appeal.

Customized according to Mohs hardness grading (5-9) to optimize wear resistance for daily wear.

Selecting high-quality gemstones is the core of creating valuable jewelry. We deeply understand the strict demands of brands for consistent raw material quality and compliance transparency. To this end, we rigorously screen each batch of gemstones using industry-standard grading standards. Through clear grading, detailed visual specification tables, and precise gemstone setting preparation, you will intuitively understand the key quality parameters and subtle differences of gemstones, ensuring every piece fits your jewelry settings for stones and overall design vision. Our meticulous gem setting and jewelry settings processes allow accurate matching of design positioning and cost requirements across different series.

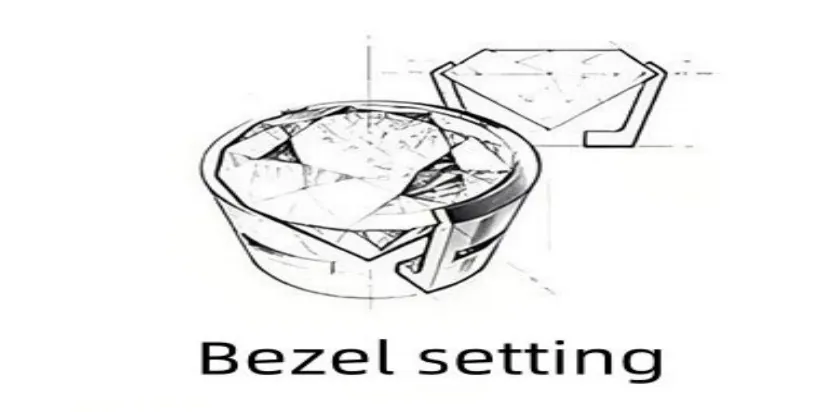

The fully enclosed structure accommodates special cuts like heart and teardrop shapes. The brass or stainless steel frame is CNC-pressed in a single step to eliminate the risk of gemstone loss, ensuring precise gemstone setting. This structure is suitable for frequently worn rings and bracelets, achieving a yield rate exceeding 99.2%, and reflects professional jewelry settings for stones and gem setting craftsmanship in every piece, providing reliable jewelry settings quality.

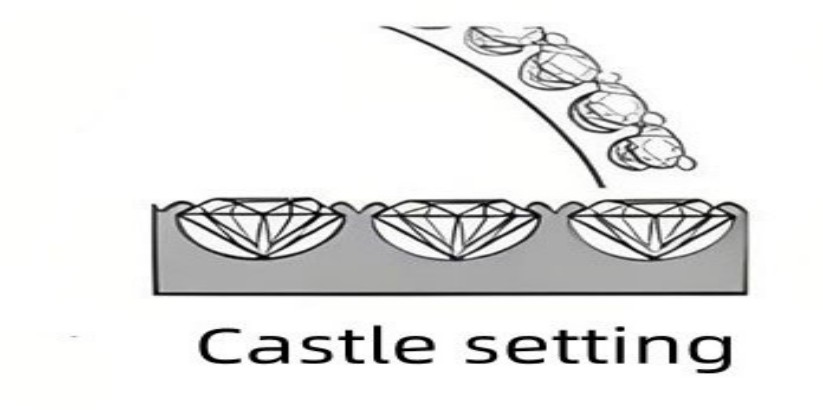

The CNC-carved teeth are precision-controlled to a tolerance of 0.3mm ± 0.05mm, ensuring the light transmittance of standard round diamonds from 2-15mm. With a monthly production capacity starting at 200,000 pieces, the system supports a tool-free, rapid stone filling process, ideal for various gemstone settings.

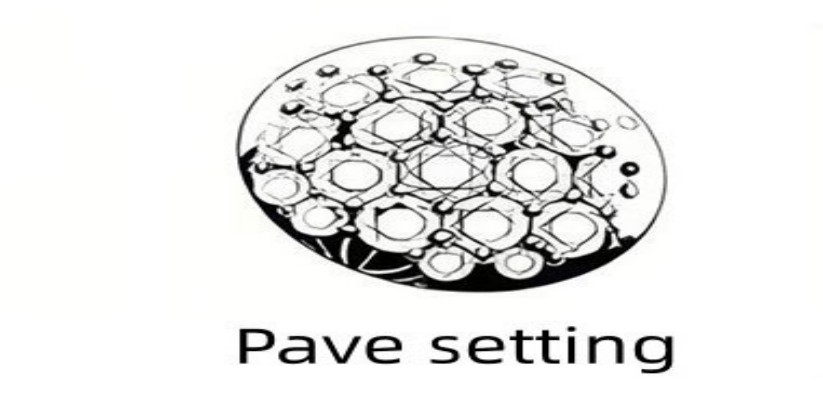

A laser-guided drilling system ensures even spacing of each 0.8-1.5mm diamond. The stainless steel base features pre-cut anti-slip grooves, and the inlay speed can reach 1,500 diamonds per hour, making it suitable for mass production of necklaces and pendants.

To address the key challenges of tension setting structure reliability and time cost, we use a precision process that combines CNC with manual fine-tuning (error ≤ 0.1mm) to complete mass production of stainless steel/copper-based jewelry within 30 days, ensuring high stability of gemstones and minimizing the risk of customer complaints.

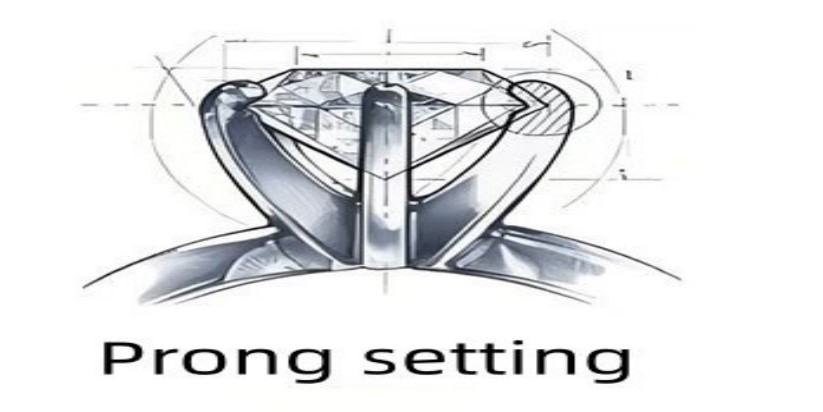

To meet the dual requirements of prong strength and wearer safety, we utilize laser-engraved stainless steel or copper substrates and a precision 36° prong angle design to ensure each gemstone is evenly supported and securely seated. We can provide fast sample delivery within 3-7 days at the fastest, and the mirror-polished interior of the prongs eliminates the risk of scratching, ensuring zero-risk craftsmanship for engagement rings and other sentimental gemstone setting jewelry.

To overcome key challenges in stone setting, such as deformation and misalignment, we utilize precision-engineered substrates made of laser-engraved stainless steel or copper (thickness ≥ 0.3mm). Through precision slot machining with an accuracy of ≤ 0.1mm, we ensure high-quality stone settings while enabling efficient mass production within 14 days. The stones are securely placed in the smooth, mirror-finished slots, reducing the risk of scratching and loosening, and ensuring optimal stability and durability.

We offer flexible production solutions. The minimum order quantity for conventional products is 300 pieces. We also support small batch trial orders (minimum order quantity 200 pieces) to verify the process, ensuring zero risk for new customers.

The standard production cycle is 25-35 days. Expedited service is provided during the proofing stage (completed within 7 working days). During the peak period of mass production, an intelligent order scheduling system is used to ensure delivery time.

Implement SH-P multiple quality control system: 1. First piece full size inspection 2. 100% full inspection, equipped with spectrophotometer, hardness tester and other professional equipment to quantify quality control standards.

The entire production process is signed with an NDA confidentiality agreement, and an independent production line is used for closed operation. Once the order is completed, the design files can be delivered to the customer to ensure the security of intellectual property rights.

We provide international test reports in accordance with SGS, LFGB, and other standards to meet REACH and CPSC regulations. We can also provide customized testing for special requirements such as California Proposition 65.

We focus on providing customers with high-quality customized jewelry solutions. Our products cover a variety of materials such as brass and stainless steel to meet the needs of different brands and market positioning. Whether you pursue classic elegance or modern fashion, we can provide a customized solution that perfectly meets your expectations, including precise jewelry settings for stones.

We provide a full range of customized jewelry solutions for substrates, including high-quality brass, 304/316L medical stainless steel, and other materials, and support the customized development of special alloys. The SH-YF metal pretreatment process can effectively improve the ductility and oxidation resistance of materials. All raw materials are tested for spectroscopy and ductility to ensure compliance with ASTM international standards, while also ensuring compatibility with precise gemstone setting.

Equipped with a CNC engraving center and 3D printing equipment imported from Germany, with an accuracy of up to 0.02 mm, it supports complex processes such as three-dimensional relief and hollow engraving, and provides structural engineering optimization to eliminate production risks, ensuring flawless jewelry settings for stones. The SH-JM digital modeling system can support rapid proofing of design drafts within 24 hours, facilitating professional jewelry settings craftsmanship.

We have established a global supply and procurement network, and can provide customized solutions for more than 2,000 gemstones, including various gemstones and cubic zirconia. We have introduced precision inlay equipment to achieve a micro-inlay accuracy of 0.3mm. Each product has been optically screened to ensure that the color difference of the gemstone is less than 0.5 levels. The SH-XQ firmness test can achieve 300 tensile tests.

Our own electroplating factory is equipped with a variety of electroplating solutions such as vacuum plating and water plating. The nano-level plating is controllable. The SH-DD electroplating standard can increase the electroplating bonding strength by more than 30%. We also provide special process options such as laser plating and gradient plating . We are equipped with a coating thickness gauge for testing.

SH Mould Center can quickly develop specific clasps, chains and other jewelry accessories, with a stock of up to 9,000+ that can be called upon at any time. Customized special accessories can be produced and delivered within 7-14 days. And all auxiliary materials have passed the EU nickel release test

For e-commerce customers, making minor adjustments to the original design, such as adding your logo or brand logo, etc. We recommend this solution for customization of name necklace fonts, projection necklace films, etc.