300 W pieces of goods delivered successfully every year

20 years of reputation is trustworthy

48-hour response plan

Restocking within 3-7 days

If it is a manufacturer problem, we will take 100% responsibility

We have established a complete after-sales service system. If there are any after -sales problems, no matter where you are in the world, we promise to respond to any quality or process issues within 48 hours and provide professional solutions. For orders that need to be reworked, we can complete the delivery of replacement parts within 3-7 working days at the fastest , and strictly control the finishing details of each product. Through the ERP system, the production files are traced throughout the process to ensure that 3D design drawings, mold data and quality inspection reports are available at any time. We also provide professional cross-border e-commerce logistics solutions to reduce the risk of transportation losses and keep your supply chain running stably.

Since 2005, star harvest has been leading the way in the R&D and manufacture of quality brass and stainless steel jewelry. We are committed to providing one-stop.

We promise to provide professional after-sales response within 48 hours and provide solutions for any process, quality or packaging issues to ensure that your sales plan is not affected after the order is delivered. We support multi-channel communication such as email, phone , online meeting , WhatsApp, etc.

If there are any quality problems caused by the manufacturer, please contact us within 7 days of arrival. We will complete the rework production in 3-7 working days at the fastest, and give priority to quality inspection and logistics. Whether it is brass decoration oxidation repair or stainless steel parts replacement , we will strictly re-inspect and deliver according to the original process standards to ensure qualified quality.

All orders are accompanied by complete production files, including 3D drawings, mold parameters, electroplating batch records, etc. Through the ERP system, one-click query of order history and quality inspection reports can be used to avoid information gaps in subsequent cooperation.

We optimize logistics solutions for European and American customers, provide anti-oxidation packaging, transportation insurance and customs clearance document pre-processing services. We cooperate with FedEx/DHL priority channels to shorten the delivery cycle by an average of 3-5 days and reduce the risk of lost items and loss.

If you encounter any problems during the cooperation process, we welcome your direct feedback. To ensure that your opinions are handled efficiently, please contact us through any of the following methods:

+86-769 8538 6106

+86-769 8155 3722

Sales6@Starharvestcn.Com

( For Inquries And Orders )

Info@Starharvestcn.Com

( For Other Information )

13794920415

Since 2005, star harvest has been leading the way in the R&D and manufacture of quality copper and stainless steel jewelry.

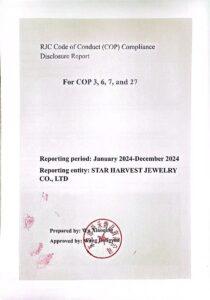

In order to improve and perfect the company’s RJC Code of Practice (COP), ensure compliance with labor, health and safety, environment, ethics and supply chain management requirements, fulfill the company’s responsible jewelry, and establish a good corporate image. This manual is compiled based on the RJC Code of Practice (COP) and combined with the company’s actual situation.

All employees of the company must strictly implement the provisions of this RJC Code of Practice (COP) and related documents. All functional departments and all employees must study carefully and implement them in earnest to ensure the establishment, implementation and continuous improvement of the RJC Code of Practice (COP) management system. The company and all employees should do the following:

1) Actively participate in various activities of the RJC Code of Practice (COP) management system, implement the RJC Code of Practice (COP), environmental, health and safety policies in their work, strive to achieve the company’s responsible jewelry management goals, and continuously improve the effectiveness and process capabilities of the RJC Code of Practice (COP) management system;

2) Comply with relevant labor, ethical, environmental, health and safety laws and regulations, fulfill corporate responsible jewelry, and establish a good corporate image;

3) Strictly implement procedural documents to ensure the effectiveness of the RJC Code of Practice (COP) management system;

4) Continuously strengthen the publicity of labor, ethical, environmental, health and safety policies related to the RJC Code of Practice (COP), continuously strengthen environmental health and safety training, improve employees’ environmental health and safety awareness, and avoid or reduce the occurrence of responsible RJC Code of Practice (COP) violations through identification and assessment of RJC Code of Practice (COP) risks, prevent environmental health and safety accidents, and reduce corporate risks.

5) The RJC Code of Practice (COP) is the guiding document for the management of the company’s RJC Code of Practice (COP). All employees must comply with it and continuously improve the company’s RJC Code of Practice (COP) management performance.

The RJC Code of Practice (COP) will be officially implemented from June 2, 2023.

When you choose to cooperate with jewelry manufacturers with ISO9001/Disney and RJC certifications, you will not only get solutions to problems, but also systematic projects to prevent problems.

The average working experience of the core members of the after-sales team is over 10 years, and they are equipped with independent quality control laboratories.