With nearly 20 years of profound experience, we focus on the customized production (OEM/ODM) of brass and stainless steel jewelry. We are familiar with the strict quality and regulatory standards of global brands (such as RoHS/REACH), and can respond quickly and provide full-link solutions from material selection, collaborative design to small-batch agile production. Relying on mature technology and strict quality inspection system, we ensure product consistency and on-time delivery, helping medium and large brands and growing e-commerce companies to expand the market with better cost and higher efficiency.

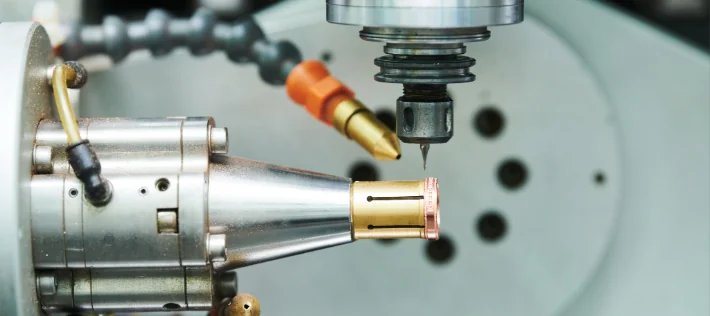

We have mature brass and stainless steel jewelry production lines with an annual production capacity of more than 4 million pieces. We are equipped with multiple precision equipment to achieve one-stop production from mold development to finished product processing.

Whether it is delicate hollow carving, multi-layer electroplating, or difficult special-shaped welding, we can accurately meet your creative needs.

Support small batch quick proofing, large batch production, and can adjust production schedule according to sales rhythm. Flexible order management mode and provide you with real-time feedback on production progress.

Average order delivery cycle is 15-25 days. Urgent needs can be communicated for expedited production. Relying on a complete logistics system and long-term cooperative freight channels, we ensure on-time delivery to the global market.

Precision mold opening technology ensures the detail restoration of each piece of jewelry, laying a precise foundation for subsequent production. It supports a variety of complex structural designs to meet your customization needs.

Equipped with an automatic wax injection machine , it maintains delicate texture after molding, provides high-precision wax patterns for the casting process, and reduces subsequent finishing losses.

The wax model is carefully trimmed by hand to remove burrs and defects, ensure smooth shaping and guarantee the exquisiteness of the final product.

Scientifically arrange the wax casting system to optimize the flow path of molten metal, improve the casting success rate and reduce the scrap rate.

The wax tree is wrapped in high-temperature resistant plaster and precisely baked to form a solid mold, ensuring a stable structure and clear details when metal is poured.

The high-temperature dewaxing process completely removes residual wax to avoid the residue affecting the purity of the metal and provides a clean and formed cavity for casting.

Professional sand casting technology is used to process special structural parts, which is suitable for heavy or special-shaped jewelry parts, ensuring metal fluidity and complete molding.

The plaster shell is removed non-destructively to preserve the original shape of the jewelry, avoid scratches or deformation, and ensure that the product is in perfect initial condition.

Precision cutting separates the castings, maintaining the integrity of each component and preparing them for subsequent assembly and finishing.

Skilled craftsmen assemble accessories by hand with precise positioning, making the multi-component jewelry structure stable and durable, and improving the overall texture of the product.

Stable high-temperature welding technology ensures that the connection points are firm and beautiful, without cracking or cold welding problems, thus extending the service life of the jewelry.

Professional technicians manually refine the metal surface to eliminate casting marks, ensure smooth lines, and improve wearing comfort and aesthetics

Multiple grinding processes create a smooth surface, from coarse grinding to fine polishing, creating a delicate touch and laying a perfect foundation for subsequent electroplating.

The high adhesion pre-plated copper layer enhances the electroplating effect, improves oxidation resistance, ensures uniform and glossy coating, and prolongs color retention time.

Laser or mechanical marking technology can clearly engrave brand logos, material identification, etc., in line with international compliance requirements .

Professional polishing technology enhances the gloss of metal, removes small scratches, and gives the finished product a high-end matte or mirror effect.

The environmentally friendly electroplating process covers 18K/24K gold, rhodium , palladium and other precious metal layers, which are anti-allergic and wear-resistant, and meet European and American environmental protection standards.

Customized lining and branded packaging solutions are scratch-resistant and anti-oxidation, improving the unboxing experience and helping to shape your brand image.

We continue to invest in the research and development of new alloys and environmentally friendly materials, such as nickel-free stainless steel (in compliance with EU nickel release standard EN 1811) and hypoallergenic brass alloy (suitable for sensitive skin). The laboratory is equipped with a spectrometer and salt spray test equipment to ensure the corrosion resistance (neutral salt spray test ≥ 72 hours without oxidation), ductility (elongation at break ≥ 20%) and cost controllability of the materials.

By optimizing electroplating formulas (such as cyanide-free gold plating) and vacuum plating (PVD) processes, we achieve precise control of coating thickness (±0.1μm), color stability (ΔE≤1.5) and wear resistance (5,000 steel wool tests without bottom exposure). The “double coating technology” (bottom layer wear resistance + surface layer color development) developed for the North American market can extend the life of gold-plated products by more than 3 times.

CNC precision engraving (accuracy ±0.05mm) and laser welding (weld strength ≥90% of base material) technologies are used to solve the burr and deformation problems of traditional jewelry production. The independently designed “multi-station linkage production line” realizes seamless switching between small batches ( starting from 200 pieces) and large batches (average 3,000 pieces per day), shortening the product delivery cycle by 30%.

We have established 12 quality inspection nodes from raw material storage (XRF spectrum detection) to finished product shipment (full inspection + AQL sampling). We have introduced AI visual inspection system (defect recognition rate ≥ 99.7%) and mechanical tester (hook durability test ≥ 2,000 times) to ensure that each product meets customer technical drawings (GD&T tolerance standards) and European and American market regulations.

SH’s self-developed TRITON-EX nickel-free vacuum ion plating technology can make 316L stainless steel and copper alloy substrates non-toxic, with a heavy metal precipitation rate of less than 0.2μg/cm² (1/50 of the EU REACH regulations). Combined with the medical-grade PVD coating circulation system, it ensures the batch stability of popular colors such as rose gold and gunmetal.

SH-LT has devoted itself to the research and development of chain technology. The single ring can bear up to 50 kg (, the anti-fading coating can withstand the test of artificial sweat for 96 hours, and the lobster clasp can withstand 500 opening and closing tests without breaking. From the 1mm ultra-thin snake bone chain to the 8mm rugged Cuban chain, each one has passed the global environmental safety standards, so that fashion and durability can be truly achieved.

From rough milling to nano-polishing, each piece of jewelry is finely polished, and the contact surface is as smooth as medical surgical steel. The exclusive mirror superposition process achieves 3 layers of light and shadow refraction, and after 100,000 friction tests, it still retains the delicate texture of oil painting brushstrokes. The minimum order of 500 pieces is fully automatic dust removal workshop, and supports FDA-grade antibacterial coating customization.

SH’s self-developed laser marking technology – the engraving depth is accurate to 0.01 mm, and the logo can remain clear and not scratched even after multiple frictions during daily wear. The minimum order is 300 pieces, and it supports QR code and micro text anti-counterfeiting. All engraved parts have 100% passed the EU nickel allergy test, making the customized LOGO clear and durable without causing skin sensitivity.

From material selection, casting, assembly to electroplating, polishing and packaging, we have set up strict quality inspection checkpoints at more than 60 key nodes, covering material composition and environmental testing (such as nickel release, lead content), physical performance testing (salt spray anti-discoloration, torque, drop, snap-fit function) and process inspection (electroplating layer thickness adhesion, polishing uniformity, welding strength) to ensure that each batch of products meets your design specifications and safety standards, and achieves stable quality delivery.

Each product undergoes more than 10 quality inspection processes, including raw material inspection, wax embryo inspection , electroplating inspection, etc. The whole process is controllable and real-time feedback of production progress is provided. AI visual inspection (defect recognition rate ≥ 99.7%) and mechanical testing (hook durability 2,000 times) are used to ensure compliance with European and American standards.

Each product has been subjected to 1000+ friction tests to ensure that the coating, electroplating and surface treatment are durable and wear-resistant. Real simulation of long-term wear and tear, strict quality control

High-precision automatic wax injection, with an error control of ±0.05mm, ensures smooth jewelry lines and precise details, reduces manual mold repair costs , and shortens sample development cycle by more than 20%.

The process from design to sample can be completed within 48 hours , supporting complex hollowing, three-dimensional carving and other fine structures, accelerating design iterations, and helping brands seize market opportunities.

The 72-hour anti-corrosion test strictly verifies the ability of stainless steel and brass alloys to resist sweat and seawater corrosion, ensuring that the product will not oxidize when worn for a long time in the high humidity environment of Europe and the United States.

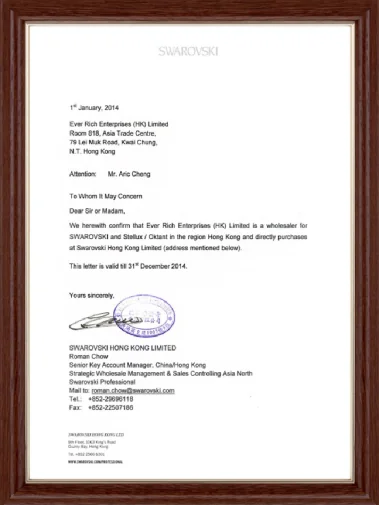

As an officially authorized partner of Swarovski crystal, we ensure that every crystal used in your custom jewelry is authentic and traceable, and is guaranteed by Swarovski’s strict quality and color standards. We provide you with reliable raw material support and avoid disputes over imitations. At the same time, we guarantee a stable and sustainable supply, which is a solid backing for you to create exquisite jewelry with brand added value and consumer trust.

We hold a valid BSCI factory inspection report and strictly follow its global social responsibility standards for production, ensuring that the custom jewelry you cooperate with is not only of high quality, but also in line with internationally recognized ethical standards, avoiding supply chain risks for your brand and providing a strong social responsibility endorsement.

We are ISO 9001:2015 certified, ensuring that the entire process from raw material procurement, production process to final delivery is strictly controlled, ensuring that the quality of your customized jewelry is consistent and stable, meeting your specifications, systematically reducing the risk of defects and improving supply chain efficiency, providing your brand with a more reliable and predictable long-term production partner.

We hold SA8000 social responsibility international standard certification and strictly follow internationally recognized labor protection, health and safety, prohibition of forced and child labor and other guidelines for production, ensuring the ethical compliance of your customized jewelry supply chain, significantly reducing human rights risks for your brand and providing strong ethical manufacturing proof, which is an indispensable compliance guarantee for you to build a responsible brand.

The material tensile strength is over 500MPa, the salt spray test anti-discoloration ≥48 hours, the key parts durability test exceeds 10,000 cycles, the product size tolerance is precisely controlled to ±0.1mm, and it complies with strict environmental protection standards such as Reach and ROHS

The average custom production cycle in the jewelry industry is 35 days. We use modular production lines to compress the mass production of copper/stainless steel jewelry to 21 days, helping you quickly seize the market.

Each factory produces an average of 30,000 pieces of jewelry per day, ensuring a zero-delay delivery record for annual orders from 200+ brands and rejecting all delivery delays.

Support 300-50,000 tiered orders per month, and complete 1,000+ small-batch reorders for 47 DTC brands in 2023 (minimum 300 pieces/item).

The production workshop is equipped with MES+ERP dual system control, realizing fully digital closed-loop management of order decomposition → raw material batch traceability → real-time process monitoring → quality tracking, and can provide feedback on order production progress at any time.

We use recycled brass + CNC optimized cutting solutions. Brass orders reduce the raw material loss rate by an average of 12%, and the overall cost is 15% lower than the quoted price of peers.

Self-developed vacuum plating process, stainless steel jewelry salt spray test up to 72 hours (normal 24 hours), brass jewelry sweat test color retention period extended to 12-36 months, leading the industry by 300%.

The sustainable material recycling system reduces the raw material waste rate to below 3%, and 97% of the raw materials can be reused. The carbon footprint in Q1 2024 is 19% lower than that of its peers, supporting the issuance of GRS certification reports.

Adopting the dual protection of blockchain drawing storage + NDA, we serve 427 brands to achieve zero leakage of design drafts, and have complete patent design and production authorization documents.