Our fully digital ecosystem transforms your copper/stainless sketches into market-ready masterpieces in ≤3 weeks – guaranteed 100% design integrity from prototype to mass production. Powered by seamless digital workflows, we eradicate costly deviations, delays, and rework while ensuring compliance with global standards. Join 500+ brands who leverage our 20-year ODM expertise for agile, risk-free scaling from 500-50,000 units. Unlock faster turnover today.

“Light customization” is an efficient personalized service model that allows consumers to create jewelry within the limited options you set (such as by selecting the font style, symbol, or short text on the name necklace), creating a “private” jewelry. This model allows you to adapt to the trend of personalized consumption and quickly launch popular categories such as name necklaces, while significantly reducing initial inventory investment and backlog risks – you only need to prepare basic components (chain, pendant base), and personalized elements (letters, symbols) are produced on demand. At the same time, it saves a lot of design and development investment, and satisfies consumers’ DIY enthusiasm by providing a selected font/symbol library.

We offer a variety of customizable fonts, including traditional serifs, clean sans serifs, and flowing scripts, allowing you to quickly develop unique styles tailored to your target audience (e.g., women’s accessories emphasize softness, men’s accessories prefer minimalism). Customization requires no additional initial fees; simply provide a design sketch or reference to ensure consistent mass production.

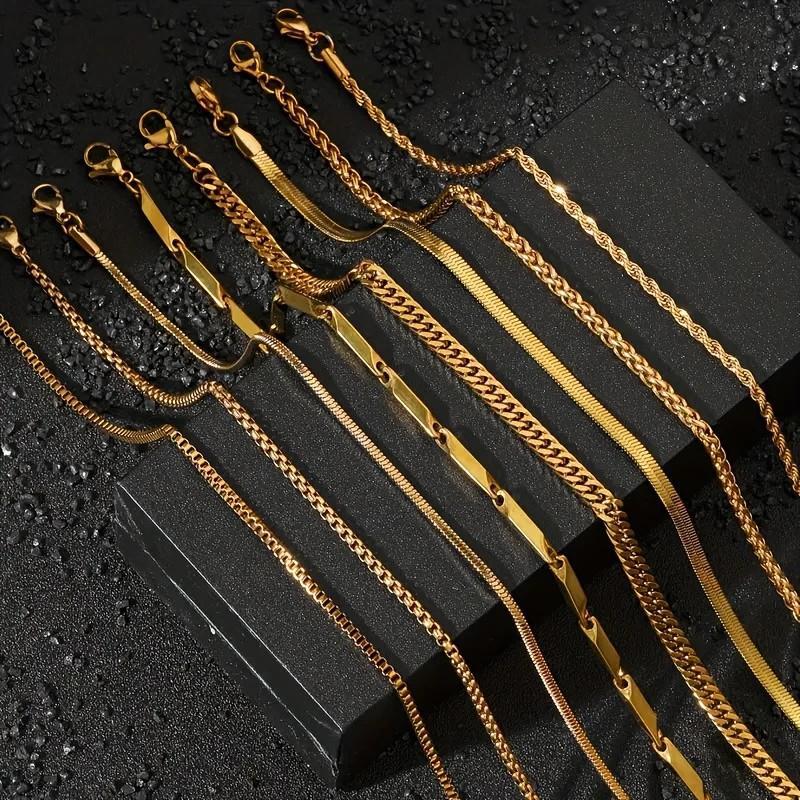

Our OEM options include gold polish, silver matte, or rose gold coating, each of which is electroplated to EU standards for environmental friendliness and meets current trends (gold for the holiday season, silver for everyday collections). These treatments are integrated into mass production, helping you maintain brand consistency and minimize production delays.

With 20 years of experience in brass jewelry customization, we have achieved a 47% higher precision of special-shaped structures than conventional casting processes based on a complete ERP system and CNC precision engraving technology with an error of 0.05mm. Through the combination of medical-grade ROHS substrate and 7-layer electroplating protection technology (including vacuum ion membrane), the color retention life of the product is extended by 3 times compared with conventional jewelry.

Laser etching (±0.03mm error) and 200+ intelligent blur templates (automatically optimizing constellation/letter burrs) are used with an acrylic diffusion layer to achieve soft light without distortion of petals. Mass production comes with 10x magnification quality inspection to ensure a yield rate of >99.2%;

CNC-carved stainless steel modules ensure the sharpness of geometric figures (error <0.05mm), acrylic diffusers achieve 92% uniform blurring of hearts/nebulae, brass bearings support the rotating color-changing gears for tens of thousands of times without damage, and vibration testing prevents component shifting.

Dark projection (red/purple) is paired with a black titanium stainless steel chain to enhance contrast, while light projection (pink/white) uses a mirrored gold-plated copper chain to brighten it by 30%. Dynamic two-color projection uses an anti-color mixing rose gold coating and has passed the EU REACH certification 500-hour sweat test without discoloration.

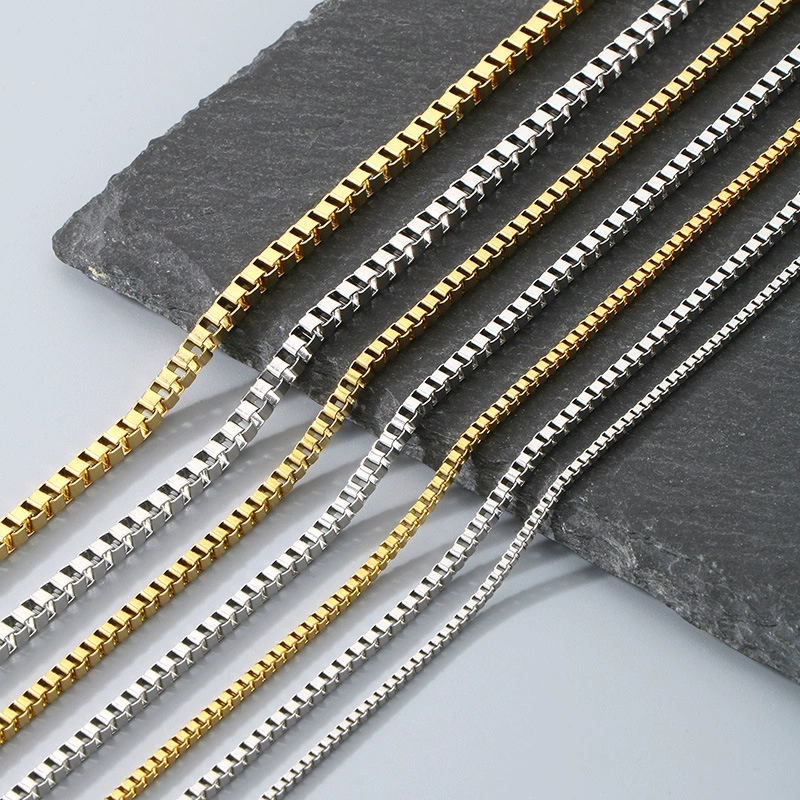

Eight-strand spiral braided stainless steel wire (single ring load-bearing 3.2kg) combined with laser seamless welding solves the problem of traditional twisted chain easily getting tangled or breaking. The brass gold-plated version is suitable for the retro series.

The fluid curved pressed brass sheet (0.6mm thick) is paired with a staggered buckle to eliminate the pain of wearing indentation, and the EU REACH coating ensures that it will not fade even after being soaked in sweat.

High-precision 304 stainless steel strips (width 2mm±0.05mm) are hydraulically flexed to achieve a natural 120° bend to fit the neck, eliminating the risk of breakage caused by a 90° hard bend.

The cube modular aluminum-copper alloy (wall thickness 1.2mm) is embedded with a nylon bushing to solve the problem of abnormal noise in sports scenes and pass the -20℃ freezing anti-embrittlement test;

Ceramic beads are nested in a 316L steel core (bead diameters are 1.5/2.0mm, dual specifications), making them eight times more wear-resistant than traditional plastic bead chains. The children’s version comes standard with a magnetic anti-lost buckle.

Diamond-cut stainless steel sheets (reflective surface > 85%) use nano-glaze sealing technology to avoid scratches on the high-gloss chain and are suitable for luxury-grade rhodium plating technology.

We offer flexible production solutions. The minimum order quantity for conventional products is 300 pieces. We also support small batch trial orders (minimum order quantity 200 pieces) to verify the process, ensuring zero risk for new customers.

The standard production cycle is 25-35 days. Expedited service is provided during the proofing stage (completed within 7 working days). During the peak period of mass production, an intelligent order scheduling system is used to ensure delivery time.

Implement SH-P multiple quality control system: 1. First piece full size inspection 2. 100% full inspection, equipped with spectrophotometer, hardness tester and other professional equipment to quantify quality control standards.

The entire production process is signed with an NDA confidentiality agreement, and an independent production line is used for closed operation. Once the order is completed, the design files can be delivered to the customer to ensure the security of intellectual property rights.

We provide international test reports in accordance with SGS, LFGB, and other standards to meet REACH and CPSC regulations. We can also provide customized testing for special requirements such as California Proposition 65.

We focus on providing customers with high-quality customized jewelry solutions. Our products cover a variety of materials such as brass and stainless steel to meet the needs of different brands and market positioning. Whether you pursue classic elegance or modern fashion, we can provide a customized solution that perfectly meets your expectations.

We provide a full range of customized jewelry solutions for substrates, including high-quality brass, 304/316L medical stainless steel and other materials, and support the customized development of special alloys. The SH-YF metal pretreatment process can effectively improve the ductility and oxidation resistance of materials. All raw materials are tested for spectroscopy and ductility to ensure compliance with ASTM international standards.

Equipped with CNC engraving center and 3D printing equipment imported from Germany, with an accuracy of up to 0.02 mm , it supports complex processes such as three-dimensional relief and hollow engraving, and provides structural engineering optimization to eliminate production risks. The SH-JM digital modeling system can support rapid proofing of design drafts within 24 hours.

We have established a global supply and procurement network, and can provide customized solutions for more than 2,000 gemstones, including various gemstones and cubic zirconia. We have introduced precision inlay equipment to achieve a micro-inlay accuracy of 0.3mm. Each product has been optically screened to ensure that the color difference of the gemstone is less than 0.5 levels. The SH-XQ firmness test can achieve 300 tensile tests.

Our own electroplating factory is equipped with a variety of electroplating solutions such as vacuum plating and water plating. The nano-level plating is controllable. The SH-DD electroplating standard can increase the electroplating bonding strength by more than 30%. We also provide special process options such as laser plating and gradient plating . We are equipped with a coating thickness gauge for testing.

SH Mould Center can quickly develop specific clasps, chains and other jewelry accessories, with a stock of up to 9,000+ that can be called upon at any time. Customized special accessories can be produced and delivered within 7-14 days. And all auxiliary materials have passed the EU nickel release test

For e-commerce customers, making minor adjustments to the original design, such as adding your logo or brand logo, etc. We recommend this solution for customization of name necklace fonts, projection necklace films, etc.