From design to finished product, we provide full OEM/ODM jewelry customization services, including material selection, production, quality control, and custom packaging. Fast proofing in 7-15 days, with ISO and European/American certification standards.

From design to finished product, we offer one-stop jewelry customization services, covering every step of the development process.

With a professional team and advanced technology, we help your brand stand out in the competitive market, from market analysis to final delivery.

Relying on the sh database, we provide analysis of styles, trends, marketing concepts, etc., helping you analyze product audiences to quickly adapt to the market

Our engineering team crafts the optimal production process from your designs and brand needs. We leverage industry expertise and material science to ensure your vision is realized with the best cost, speed, and stable, quantifiable quality.

Our professional team of designers will create 3D drawings based on your design concepts or sketches, and provide real-time feedback on your needs to ensure that the design perfectly meets your expectations.

Prototyping is available in as little as 3-15 days. Multiple copper/stainless steel versions are available for comparison. Material, plating, inlay and other processes can be adjusted, allowing for rapid finalization of product designs.

We can produce and deliver 300,000-500,000 products every month

We understand the needs of our customers, and combined with our experience and control of product process details, we help customers formulate product quality standard outlines. Our process engineering team will formulate specific quality requirements for each SKU product, including process parameters, etc., to achieve the highest quality and the most reasonable cost with the most appropriate process, and ensure stable and sustainable quality development.

We are keen on exploring new technologies, whether it is developing new processes such as environmentally friendly coatings, anti-allergic metals, special texture patterns, etc., to provide exclusive technical support for your brand

Create your own packaging method according to your brand needs to enhance the brand premium space . And we can also label the packaging according to your packaging requirements.

We can provide the best logistics solution according to your needs to ensure safe, smooth and fast delivery to your designated place.

It can be shipped in bulk, in batches, or directly to terminal stores or consumers around the world.

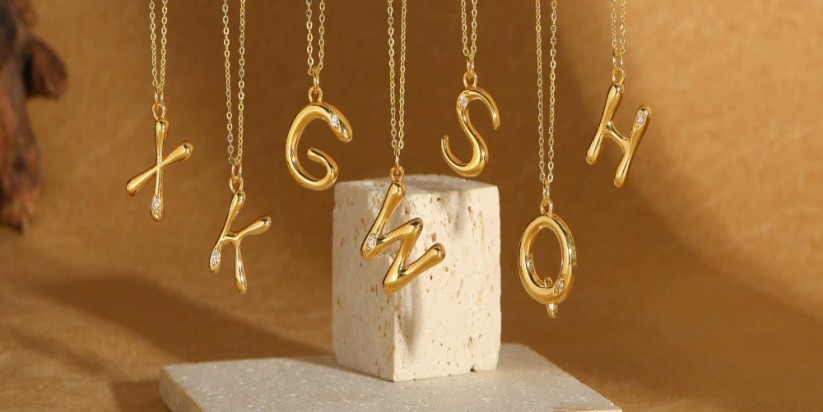

We provide shooting services such as white background pictures, scene pictures, product details pictures, etc., which meet the needs of e-commerce brands such as websites, Amazon/ Etsy , and reduce your later operating costs.

Relying on the sh database, we provide analysis of styles, trends, marketing concepts, etc., helping you analyze product audiences to quickly adapt to the market

In 2005, we built the brilliant cornerstone of Guangdong Aiyu Lighting in Guzhen, Zhongshan City, the lighting capital of the world

In 2005, we built the brilliant cornerstone of Guangdong Aiyu Lighting in Guzhen, Zhongshan City, the lighting capital of the world

In 2005, we built the brilliant cornerstone of Guangdong Aiyu Lighting in Guzhen, Zhongshan City, the lighting capital of the world

In 2005, we built the brilliant cornerstone of Guangdong Aiyu Lighting in Guzhen, Zhongshan City, the lighting capital of the world

In 2005, we built the brilliant cornerstone of Guangdong Aiyu Lighting in Guzhen, Zhongshan City, the lighting capital of the world

In 2005, we built the brilliant cornerstone of Guangdong Aiyu Lighting in Guzhen, Zhongshan City, the lighting capital of the world

In 2005, we built the brilliant cornerstone of Guangdong Aiyu Lighting in Guzhen, Zhongshan City, the lighting capital of the world

From OEM jewelry design to final delivery, we ensure full transparency throughout the entire process, with efficient communication and strict quality control.

At every stage, clear milestones are set. A dedicated team member will provide real-time feedback on your order, allowing you to track and manage the progress of your OEM jewelry production every step of the way.

Both parties sign NDA confidentiality agreement to protect your design

Based on your design draft/product requirements, we will issue a quotation within 24-48 hours (FOB unit price | mold fee | MOQ)

Draw 3D engineering drawings according to your design in 72-96 hours (with tolerance analysis), and enter the proofing stage after you confirm the design

The first sample will be delivered within 3-15 business days. Once you confirm that the sample is correct, the next step of production will begin.

Pay 30% advance payment after the first sample is approved, the production process is fully transparent, and feedback the production progress to you in real time

We will conduct sampling inspections according to the quality standards of qualified samples and issue an “Interim Quality Confirmation”.

Make packaging materials according to your brand specifications , and upload packaging inspection video simultaneously

We will ship within 48 hours of receiving the final payment (DDP/DAP supported) and provide a quality control inspection report. Third-party inspection is welcome.

At StarHarvest, we provide one-stop OEM Jewelry solutions, offering everything from design and material selection to production and delivery. With over 20 years of experience, we ensure high-quality, fast-turnaround OEM Jewelry services that meet market demand. Our expert team, advanced technology, and rigorous quality control process guarantee precision, reliability, and sustainable production, all while helping your brand stand out in a competitive market.

Since 2005, we have been focusing on the production of brass/stainless steel jewelry with mature technology and stable quality.

A minimum order of 200 pieces / item , quickly responds to the needs of emerging brands, and reduces inventory pressure.

A minimum order of 200 pieces / item , quickly responds to the needs of emerging brands, and reduces inventory pressure.

From design to sample, we can make the cycle as fast as 7-15 days, which can shorten the development cycle and speed up the product launch.

From material procurement, production and processing to quality inspection and packaging, all are completed in our own factories to ensure stable delivery and quality

We provide special electroplating, laser engraving, texture patterns and other self- developed technologies to help your brand establish exclusive product tonality.

Unique SH-P quality system and multi- step QC process ensure that each product meets your needs and reduces quality issues.

Sufficient production capacity allows timely stocking regardless of peak or off-peak seasons, helping you respond efficiently to changes in market demand.

We understand that in the competitive jewelry market, standing out is crucial. Our Private Label jewelry customization services are designed to address the key pain points brands face—ensuring that each product conveys your brand concept while meeting market demand.

At Star Harvest, we specialize in professional and flexible OEM customization services tailored to meet your brand’s unique positioning and market demands. From raw materials to finished products, we ensure stable quality and reliable delivery for every project, whether it’s creating new designs, optimizing existing products, or supporting brand differentiation.

Our OEM jewelry services are designed to provide comprehensive support at every stage of the production process. Here’s how we can help you elevate your jewelry brand

We specialize in OEM/ODM customized production of brass and stainless steel (316L/304) jewelry, providing full-process customization of material hardness, thickness, surface treatment (polished/brushed/vintage/PVD gold-plated rose gold, etc.), and can quickly produce samples within 7-10 days to verify the feasibility of the design. At the same time, we support environmentally friendly coatings and low-sensitivity alloys to ensure that products meet global market standards.

Over 20 years of experience in jewelry customization, with a total of 12,000+ brass/stainless steel styles developed. Industrial-grade 3D scanners (±0.03mm accuracy) achieve millimeter-level restoration of design drafts, maintaining material hardness and color consistency from samples to bulk goods. Each product design provides NDA agreement signing, sample packaging material development and export compliance certification hosting. You only need to focus on design, and leave the rest of the production supply chain to us for execution.

SH provides a variety of gemstone options, including natural gemstones directly mined from mines/laboratory-grown diamonds/artificial gemstones. You can freely choose according to your needs. All gemstones are certified with IGI/GIA dual certificates, and support customized solutions from special-shaped cutting to micro-setting processes, as well as complying with RJC system metal traceability standards. 48-hour ultra-fast proofing reduces development risks.

We can provide various electroplating layers, such as 10k, 14k, 18k, 22k according to your needs, and support various electroplating color options such as single color, multi-color, gradient, etc. The use of SH-type vacuum coating technology can achieve electroplating color retention > 3 years wear test cycle (in line with en 12472 artificial sweat test), the special color plating solution library supports accurate restoration of metal color numbers, and the electroplating solution ingredients can be traced, and simultaneously meet the rohs/reach heavy metal migration control requirements.

Supports the design and development of 127+ jewelry accessories such as chains, clasps, and link rings. Years of fine processing and manufacturing experience ensure lead-free solder joints and Astm F2923 tensile strength standards. Equipped with german precision cutting equipment, jewelry accessories can achieve a processing tolerance of less than 0.1mm, logo stamping and packaging materials one-stop customization, and supports a variety of materials such as brass and stainless steel, in compliance with annex xvii of reach regulations.

Over 20,000+ brass and stainless steel basic style libraries, you can choose any modification, including logo stamping, size adjustment, accessory replacement, font elements, pattern customization and other requirements. All products meet environmental certification and can provide corresponding quality inspection reports, and comply with ISO 9001 quality system and Amazon FBA packaging specifications, helping you to quickly distribute products with minimal development costs.

We offer flexible production options. The minimum order quantity for standard products is 300 pieces. We also support small trial orders (starting from 200 pieces) to validate the production process and ensure minimal risk for new customers.

The standard production cycle for orders is 25-45 days. If you require expedited sampling, we will proactively communicate to prioritize production scheduling, and the first sample can be delivered within one week. During peak production periods, we have an ERP order scheduling system to ensure on-time delivery.

Implement SH-P multiple quality control system: 1. First piece full size inspection 2. 100% full inspection, equipped with spectrophotometer, hardness tester and other professional equipment to quantify quality control standards.

All our work begins only after an NDA confidentiality agreement is signed. The entire production process is kept confidential and uses a separate, closed production line. Design documents are only delivered to the client after the order is completed to ensure intellectual property security.

We have our own quality laboratory to conduct quality testing, and we can also provide third-party testing reports to ensure that we meet global quality standards.

As a leading B2B jewelry factory, we’re proud to have established long-term partnerships with numerous high-end global fashion and jewelry brands, including renowned international retailers and designer labels. However, due to our strict adherence to non-disclosure agreements (NDAs) to protect our clients’ trade secrets and intellectual property, we cannot disclose specific brand names. This reflects our company’s strength, integrity, and professionalism—our ability to provide high-quality custom brass and stainless steel jewelry to top brands. If you’re a potential partner, please contact us through our official website to learn more about collaboration opportunities. Let’s work together to drive your brand’s success.

We employ a proprietary electroplating process to ensure our brass and stainless steel jewelry achieves the highest industry standards for surface treatment. As a professional B2B jewelry manufacturer, our electroplating process boasts superior corrosion resistance and fade resistance, guaranteeing lasting luster. (For example, the electroplating thickness meets international ISO standards and comes with a salt spray test report, ensuring a lifespan 2-3 times longer than our competitors under normal use conditions, and stainless steel is compatible with PVD plating.) We continuously optimize our electroplating process and implement rigorous quality control procedures (such as batch sampling inspection) to meet the high-end customization needs of designers and brand owners.

Our factory’s core manufacturing expertise focuses on brass and stainless steel jewelry. These materials offer excellent durability, luster, and cost-effectiveness, making them our strengths in mass-producing high-quality B2B products. In addition, we also support customization of other materials, including silver and other special alloys (such as copper alloys or environmentally friendly metals), suitable for high-end fashion designs or specific market needs. No matter what material you need, we can provide one-stop service from design to mass production.

We are a B2B factory focused on providing customized services (including OEM and ODM). We do not engage in wholesale or retail business. This means we do not directly sell inventory, accept bulk purchases of finished products (like traditional wholesale), or conduct retail transactions with end consumers. Instead, we partner with corporate clients (such as brands, designers, or retailers) to custom-produce brass, stainless steel, and other jewelry to your needs (i.e., full customization from design to delivery).

At our factory, we implement a multi-layered quality control system to ensure that every piece of jewelry meets stringent professional standards. This includes:

Material Screening: We only use brass, stainless steel, and other designated materials (such as silver) that meet industry standards. Each batch of raw materials undergoes chemical composition and durability testing to eliminate sources of inferior quality or contamination.

Production Process Monitoring: We implement spot checks and sampling throughout the entire production process (from design and mold making to surface treatment) to ensure consistency in key parameters (such as dimensional accuracy and plating gloss). Automated equipment is used to reduce human error.

Finished Product Inspection and Certification: Every batch undergoes 100% visual and functional inspection (including wear resistance, allergy resistance, and structural strength), and third-party certifications (such as SGS lead-free certification or EU REACH compliance) are provided upon request.

Continuous Optimization: We optimize our quality processes through customer feedback and regular internal audits (referring to the ISO 9001 framework).

We guarantee consistent quality, regardless of order size. If you have specific quality standards (such as environmental requirements), please contact us for a customized solution. We can provide sample test reports or provide an online consultation for immediate response!