SH insists that high-quality products are the lifeline of the enterprise. The highest quality standards in the industry.

Rigorous and scientific quality management system.

StarHarvest ‘s unique SH-P quality system can ensure that the incoming material inspection pass rate exceeds 97% and the

finished product pass rate reaches more than 98%, providing you with high-quality jewelry that has been effectively tested

and certified.

Strict SH-QS quality control standards, 100% quality control

compliance of material composition , IPQC of each production process from casting to electroplating,

100% FQC of each finished product and OQC of each packaged and packed jewelry

All raw materials are strictly tested and traceable. We insist on using only 100% environmentally friendly materials. The brass and stainless steel materials used meet international standards

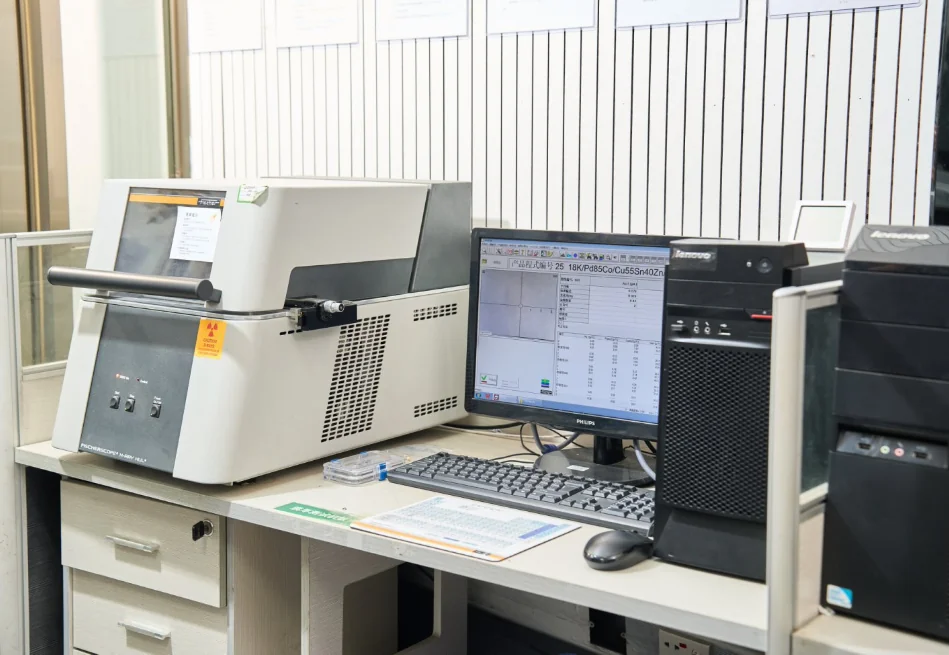

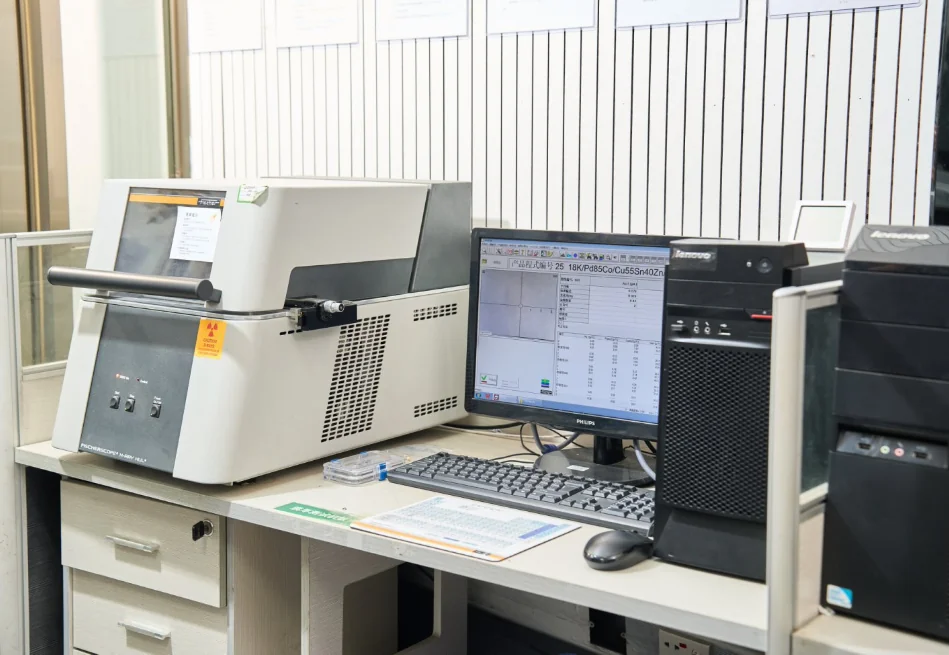

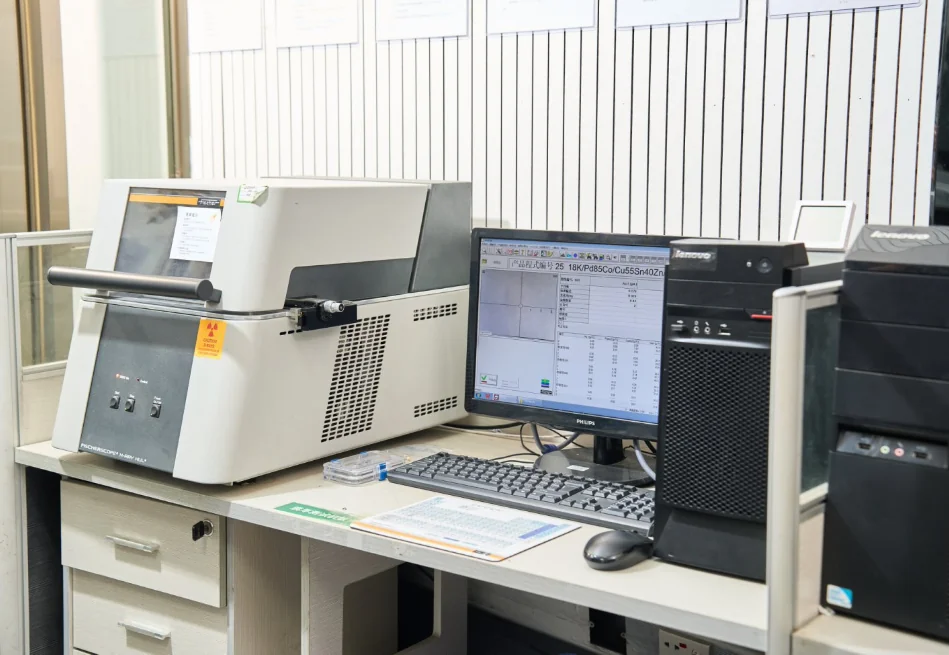

Each product will undergo pre-plating and post-plating testing before electroplating, and must be tested by an X-ray fluorescence thickness gauge to ensure that the coating meets your needs

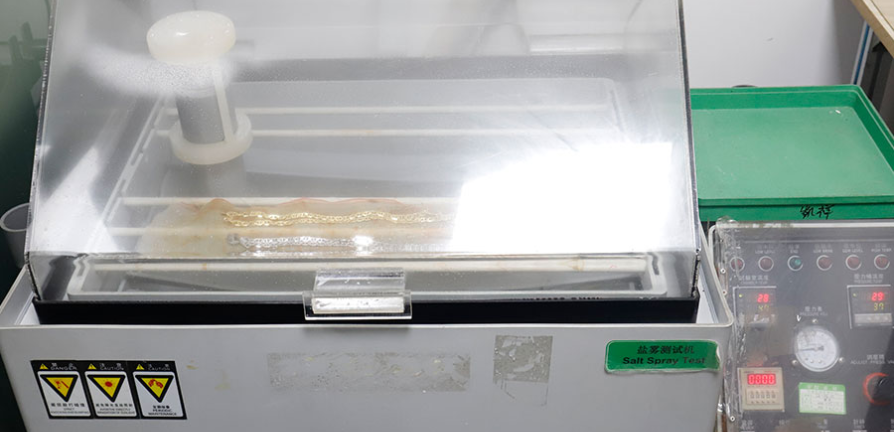

SH is equipped with its own laboratory, and each product can exceed the industry standard by 50% corrosion resistance, effectively extending the product life

In addition to 8 quality inspections in the production stage, SH also requires 3 QC inspections after the finished product is qualified. We can ensure that each product is 100% compliant

SH insists that high-quality products are the lifeline of the enterprise. The highest quality standards in the industry. Rigorous and scientific quality management system

Relying on 20 years of global market service experience, we have built a full-link standardized quality control system: from material safety screening of raw materials entering the warehouse, to production error control throughout precision manufacturing, to independently executed multi-dimensional safety testing and batch traceability mechanism, to ensure that each batch of customized jewelry meets the dynamic requirements of target market regulations, so that you can avoid the anxiety of quality fluctuations and focus on improving brand value.

Spectrometer to detect the purity of raw materials and check the supplier’s report

Full-size measurement of 3 samples before each batch of production

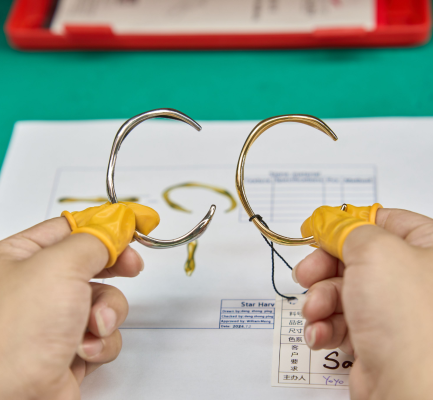

Full inspection of each product

In each production link, a dedicated inspection QC and manager will randomly inspect at least 5 pieces per hour , focusing on welding/grinding

X-ray thickness gauge randomly detects coatings

100% visual inspection + 5% salt spray test sampling

3 pieces are randomly removed from each box for retesting

Before each batch of brass and stainless steel raw materials enters the warehouse, they must be tested by spectrometer, hardness test and surface condition check to ensure purity ≥ 99.9% and no impurities. We use international metal standards (such as ASTM/EN) to compare data, and unqualified batches are directly returned to eliminate quality risks from the source. All test data are archived for 15 years to ensure full traceability, providing you with reliable basic jewelry raw materials.

Based on the SH material database, we use a triple locking mechanism of spectral screening, alloy ratio verification and environmental protection limit to ensure that basic materials such as brass and stainless steel meet the dynamic regulatory thresholds such as REACH and F2923 from the moment they enter the warehouse, eliminating the risk of excessive nickel release or heavy metal migration, saving you 35% of the cost of incoming material sampling

Based on the SH material database, we use a triple locking mechanism of spectral screening, alloy ratio verification and environmental protection limit to ensure that basic materials such as brass and stainless steel meet the dynamic regulatory thresholds such as REACH and F2923 from the moment they enter the warehouse, eliminating the risk of excessive nickel release or heavy metal migration, saving you 35% of the cost of incoming material sampling

Based on the SH material database, we use a triple locking mechanism of spectral screening, alloy ratio verification and environmental protection limit to ensure that basic materials such as brass and stainless steel meet the dynamic regulatory thresholds such as REACH and F2923 from the moment they enter the warehouse, eliminating the risk of excessive nickel release or heavy metal migration, saving you 35% of the cost of incoming material sampling

From wax model carving to electroplating molding, our online quality inspection monitors every link in real time to ensure process accuracy and product stability. Standardized sampling inspection combined with full inspection eliminates batch risks and ensures that your order is delivered with zero defects.

Point copywriting

100% qualified finished product rate, each piece of jewelry undergoes final inspection before leaving the factory to ensure compliance with international quality inspection standards. We use a manual + equipment double verification mode, with a third-party certification report, to support customers on-site inspection

Check each piece for surface polishing (no scratches or burrs) and mounting firmness (tensile test ≥ 10 N). Use gem tweezers to check the fit of accessories to prevent looseness or misalignment.

We sample the entire batch of products according to AQL 2.5 standards, check the shipping marks , packaging integrity and metal allergy test report (EN 1811:2011 passed), and ensure that the goods are 100% matched with the order before sealing and shipping.

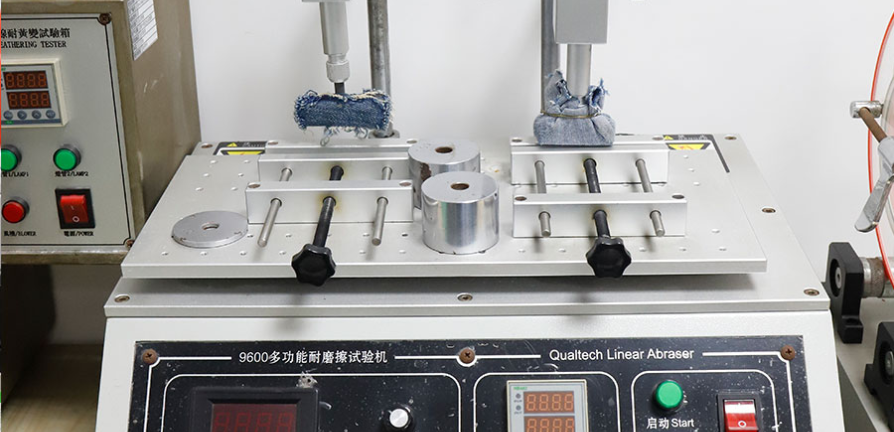

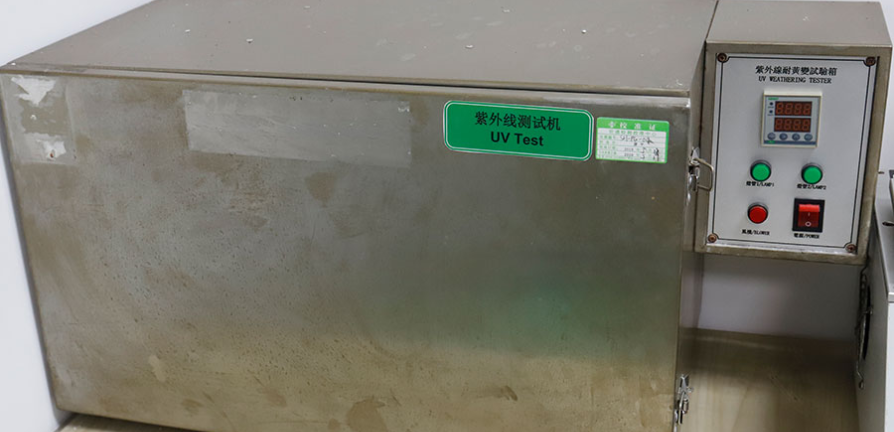

SH is equipped with high-standard laboratory equipment, all equipment is calibrated regularly, and the test reports can be traced back to international standards. Data-based testing is used to ensure the durability, safety and compliance of jewelry . In addition, products are regularly sent to third-party verification and testing.

The accelerated test simulates the wearing environment (5% NaCl solution) for 48 hours to verify the corrosion resistance of the coating and ensure compliance with European and American nickel release standards (EN 1811:2011).

Use standard 0000# steel wool and rub it 500 times at a pressure of 500g to test the wear resistance of the coating, and provide digital feedback on the risk of discoloration or shedding (grade ≥4 is qualified).

Accurately measure the load-bearing capacity of key parts such as chains and buckles (≥15 – 50N without breaking), eliminate problems such as hook deformation and welding cracking, and ensure wearing safety.

Our brass/stainless steel products must undergo a rigorous 72-hour tumble test on a tumble tester before leaving the factory. Based on the ASTM transportation test standard, through preset high-speed rotation, multi-angle drops and continuous impacts, we proactively expose hidden dangers such as the risk of jewelry buckle breakage, minute cracks in the electroplating layer, and the probability of loosening of inlaid accessories. This ensures that OEM/ODM ordered jewelry can withstand multiple transit bumps in sea and land transportation, reducing the transportation loss rate of your customized products to less than 2%, and the intact rate for consumers exceeds 99%.

Each lobster clasp is tested by a custom buckle tester for cyclic opening and closing (ASTM F2923 standard), simulating the extreme external force scenarios of pulling and accidental contact during daily wear, and accurately recording the critical fatigue value of the buckle spring, the deformation threshold of the card slot, the wear cycle of the electroplating layer, etc. Our brass/stainless steel lobster clasp can bear a load of 35N, and the opening and closing life exceeds 5,000 times (the industry average is 3,000 times), and the defective rate of factory products is reduced to less than 0.3%.

Each batch of brass/stainless steel raw materials and finished products are tested by a high-sensitivity environmental testing machine (GC-MS/ICP-OES combined) to accurately screen the release of lead, cadmium and nickel. We identify hidden risks such as electroplating solution residues, metal allergens, and phthalates in plastic accessories in advance to ensure that your custom jewelry has a zero recall record and avoid cross-border customs detention and consumer health litigation disputes.

When your peers choose to cooperate with you for more than 3 consecutive years: What the brand supply chain manager says

James Carter

Purchasing Manager

“We Have Been Working With Starharvest For Over 3 Years And Their Quality Control Is Impeccable. In Our Recent Order Of 50,000 Pieces, Their Stainless Steel Chain Had A Defect Rate Of Less Than 0.5%. What Impressed Us Most Was That They Proactively Provided A Report On The Plating Thickness Before Shipping – Exactly The Kind Of Diligence We Need.”

“As A Fast-Growing Dtc Brand, We Value Their 45-Day Standard Turnaround On Custom Designs. They Produced Our Geometric Brass Collection With Perfect Symmetry – All 120 Angles Were Within 0.1mm Tolerance. Their Production Updates Every 48 Hours Gave Us Total Visibility.”

“Their Material Certification System Is Thorough. Each Copper Alloy Batch Comes With Mill Test Reports Showing Exact Composition. When We Requested Lead-Free Compliance Documentation For Eu Market, They Provided Full Test Reports Within 12 Hours. This Level Of Professionalism Is Rare.”

“Star Harvest’S Responsiveness Saved Us A Major Holiday Production. When We Needed A Last-Minute Modification To A Stainless Steel Pendant, Their Engineering Team Had Cad Adjustments Ready Within 6 Hours. Their Sample Accuracy Means We Can Now Skip Prototyping—The First Batch Is 95% Production-Ready.”

“Their Brass Finishing Consistently Meets Our High Standards. We’Ve Ordered 7 Different Antique Finishes Over 18 Months – Every Batch Matches The Approved Master Sample Exactly. Oxidation Resistance Testing Showed 30% Better Performance Than Our Previous Vietnam Supplier.”

“Their Defect Replacement Policy Is Outstanding. When 2% Of A Brass Ring Shipment Showed Casting Flaws (Our Qc Found It), They Air Shipped Replacements In 3 Days Without Paperwork Delays. We’Ve Reduced Inspection Costs By 40% Since Switching To Them.”

Every piece of jewelry is carefully inspected before leaving the factory, but if you find any problems, please feel free to contact our after-sales team. We promise to respond within 48 hours and provide solutions such as exchange, return or refund to ensure that your order is always safe and reliable.