Custom electroplating is a surface treatment process for metal jewelry. Electrochemically, a thin layer of metal coating (such as yellow gold, rose gold, or black gold) is added to a brass or stainless steel base to achieve a specific color, luster, and durability, making it ideal for gold plating jewelry. This allows brands to fully control the visual style of their products, from classic luxury to modern fashion, while ensuring corrosion resistance, fade resistance, and wear resistance—perfectly meeting the environmental and aesthetic demands of the European and American markets. As part of our jewelry plating service, we integrate ODM/OEM processes, simplifying custom gold plating color standardization and production efficiency, ensuring a seamless transition from concept to mass production for your brand’s designs.

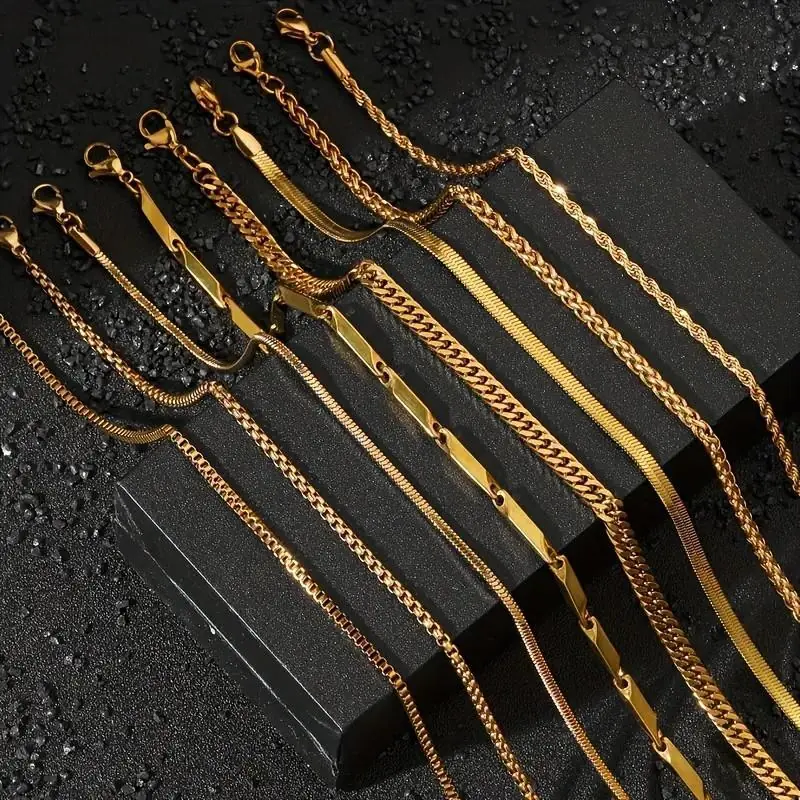

The 18K high-saturation warm-toned coating precisely matches the Pantone 18-1345 luxury color standard, while the 14K light gold version optimizes the red and copper ratio to achieve a fast, fashionable, lightweight, and neat wearing effect. Both standards have passed the 72H salt spray test, making them ideal for custom gold plated jewelry and gold plating jewelry that meet high-quality aesthetic and durability requirements. Achieve perfect 18K warmth or trendy 14K light gold for your custom gold plated jewelry. Deep, saturated tones match premium color standards, while optimized lighter shades offer a fast, fashionable finish. Both ensure enduring quality for high-end gold plating jewelry, meeting demanding aesthetic and durability expectations.

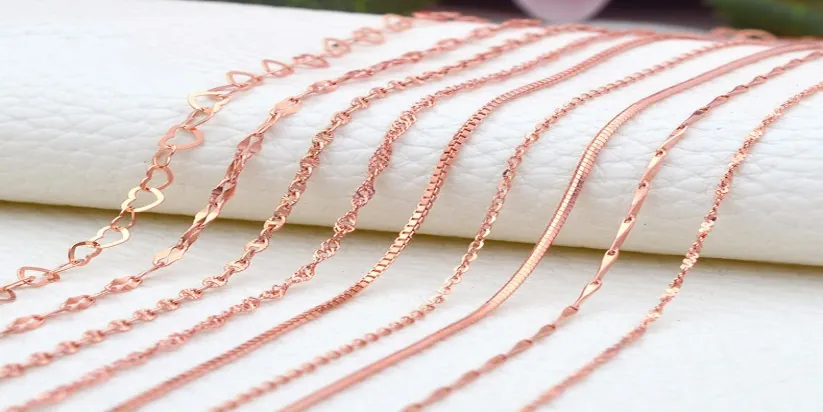

The palladium-enhanced rose gold plating eliminates the cheap powdery feel, and our exclusive matte etching process—supported by our gold plating jewelry service—combines delicate touch with fingerprint resistance. ΔE < 1.5 after 100 cleanings ensures the long-lasting beauty of custom gold plated jewelry for wedding collections. The palladium-enhanced rose gold plating eliminates the cheap powdery feel. Boosted by our gold plating jewelry service, the exclusive matte etching process combines a delicate touch with fingerprint resistance. This ensures long-lasting beauty for your custom gold plated jewelry in wedding collections.

The 18K palladium-rhodium alloy coating achieves a mirror-grade cool white light (reducing costs by 30%), and the 14K light platinum version presents a Korean blue-white luster. Enhanced through custom gold plating jewelry service, the entire series complies with the EU nickel release standard (<0.2μg/cm²/wk). Achieve a striking mirror-grade cool white shine with our 18K palladium-rhodium alloy coating, offering exceptional value. For a popular Korean blue-white luster, choose the elegant 14K light platinum finish. Enhanced via our custom gold plating jewelry service, the entire collection delivers guaranteed safety, meeting stringent international compliance standards.

Medical-grade PVD black plating technology covers the 316L stainless steel base. The 0.5μm dense coating increases scratch resistance by 70%, and the salt spray test is 96 hours without any spots.

The controlled oxidation process simulates the natural aging effect of 3–5 years, while the oil-sealing and curing technology locks in the staged patina texture. With support custom gold plating, the mass production yield of American retro-style hang tags reaches 95%+. Our accelerated oxidation process achieves the rich patina of 3–5 years of natural aging. Advanced oil-sealing curing technology preserves this vintage texture permanently, while custom gold plating options ensure product diversity. This integrated approach delivers a 95%+ yield on American retro-style hang tags.

Zinc-tin particles are added to the 14K base to create a soft, warm tone, suitable for the gradient pearlescent needs of heavy earrings. The anti-discoloration life is extended by 40% after ASTM D4060 testing.

Deviations in gold plating thickness will directly erode your profits – choosing 0.1-0.3μm (color retention for 3-6 months) is suitable for fast-moving fashion items, but the return rate in the European and American markets has climbed 37%; 1.5-2.0μm (color retention for 3-5 years) reduces warranty costs by 19% (data from partner brands), and is particularly suitable for long-term sales of classic items. We provide full custom gold plating parameter customization (0.1-5.0μm), combined with your brand positioning (such as DTC emerging brands using 0.5-1.0μm to balance cost-effectiveness, and high-end lines using 2.0μm+PVD process to pass ISTA sweat corrosion testing), free sample delivery to verify the actual color retention period, and avoid the risk of declining gross profit margins due to excessive gold plating or negative reviews caused by insufficient thickness, making it ideal for gold plating jewelry services. Deviations in your custom gold plating thickness silently erode profits—insufficient plating drives high return rates in key markets like Europe/America, while excessive thickness inflates material costs. Precise thickness matching is essential: lightweight coatings for fast fashion’s short lifecycle, or durable gold plating jewelry services for premium/classic pieces (proven to cut warranty costs per brand partners). We eliminate dual risks—margin-crippling over-plating and negative reviews from premature fading—by tailoring specifications to your brand positioning. Validate optimal performance risk-free with pre-production samples, securing profit-protected longevity for every collection.

We offer flexible production solutions. The minimum order quantity for conventional products is 300 pieces. We also support small batch trial orders (minimum order quantity 200 pieces) to verify the process, ensuring zero risk for new customers.

The standard production cycle is 25-35 days. Expedited service is provided during the proofing stage (completed within 7 working days). During the peak period of mass production, an intelligent order scheduling system is used to ensure delivery time.

Implement SH-P multiple quality control system: 1. First piece full size inspection 2. 100% full inspection, equipped with spectrophotometer, hardness tester and other professional equipment to quantify quality control standards.

The entire production process is signed with an NDA confidentiality agreement, and an independent production line is used for closed operation. Once the order is completed, the design files can be delivered to the customer to ensure the security of intellectual property rights.

We provide international test reports in accordance with SGS, LFGB, and other standards to meet REACH and CPSC regulations. We can also provide customized testing for special requirements such as California Proposition 65.

We focus on providing customers with high-quality custom gold plated jewelry solutions. Our products cover a variety of materials such as brass and stainless steel to meet the needs of different brands and market positioning. Whether you pursue classic elegance or modern fashion, we can provide a gold plating jewelry service that perfectly meets your expectations, ensuring every piece benefits from professional jewelry plating service.

We provide a full range of gold plating jewelry and customized jewelry solutions for substrates, including high-quality brass, 304/316L medical stainless steel, and other materials, and support the customized development of special alloys. The SH-YF metal pretreatment process can effectively improve the ductility and oxidation resistance of materials. All raw materials are tested for spectroscopy and ductility to ensure compliance with ASTM international standards, making every piece suitable for custom gold plating applications.

Equipped with a CNC engraving center and 3D printing equipment imported from Germany, with an accuracy of up to 0.02 mm, it supports complex processes such as three-dimensional relief and hollow engraving, and provides structural engineering optimization to eliminate production risks. The SH-JM digital modeling system can support rapid proofing of design drafts within 24 hours, making it ideal for custom gold plated jewelry services.

We have established a global supply and procurement network, and can provide customized solutions for more than 2,000 gemstones, including various gemstones and cubic zirconia. We have introduced precision inlay equipment to achieve a micro-inlay accuracy of 0.3mm. Each product has been optically screened to ensure that the color difference of the gemstone is less than 0.5 levels. The SH-XQ firmness test can achieve 300 tensile tests.

Our own electroplating factory is equipped with a variety of electroplating solutions such as vacuum plating and water plating. The nano-level plating is controllable. The SH-DD electroplating standard can increase the electroplating bonding strength by more than 30%. We also provide special process options such as laser plating and gradient plating . We are equipped with a coating thickness gauge for testing.

SH Mould Center can quickly develop specific clasps, chains and other jewelry accessories, with a stock of up to 9,000+ that can be called upon at any time. Customized special accessories can be produced and delivered within 7-14 days. And all auxiliary materials have passed the EU nickel release test

For e-commerce customers, making minor adjustments to the original design, such as adding your logo or brand logo, etc. We recommend this solution for customization of name necklace fonts, projection necklace films, etc.