As a jewelry buyer or international brand owner, the decision of material selection within a professional jewelry factory is crucial for your product’s success. The fundamental question we frequently address for our partners in the jewelry factory is: what type of stainless steel is best for jewelry to guarantee longevity and customer satisfaction for the global market?

At Star Harvest, we leverage over 20 years of experience as a leading stainless steel jewelry manufacturer. Our answer is unequivocal: 316L stainless steel. This material, often referred to as surgical-grade steel, provides the superior quality and hypoallergenic properties that modern consumers demand, setting the expert standard for the industry.

Manufacturing Excellence and Material Integrity

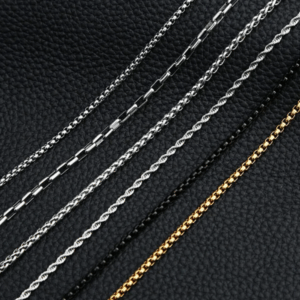

At Star Harvest, we understand that quality in a high-capacity jewelry factory starts at the chemical composition level. While other grades exist, 316L stands out in our jewelry factory due to the critical addition of Molybdenum. This element significantly boosts the material’s resistance to corrosion from sweat and saltwater—the common factors that cause inferior jewelry to tarnish. Choosing 316L for your collection in a professional jewelry factory is a non-negotiable step toward ensuring your brand’s reputation for enduring quality among mid-to-large scale retailers.

Advanced Capabilities and Quality Systems

Our expertise as a leading jewelry factory goes far beyond sourcing. As a premier OEM/ODM partner, we provide B2B capabilities that guarantee market readiness for international brands:

Rigorous Quality Control: Our in-house jewelry factory QC laboratory implements 9 distinct quality control checks. Every electroplating batch in the jewelry factory undergoes an intensive 72+ hours salt spray test, ensuring your products meet the highest standards for color retention and wear resistance expected by fast-growing e-commerce brands.

Patented Structural Innovation: We integrate exclusive technical solutions into production. For instance, our proprietary custom stainless steel jewelry anti-allergy treatment provides an extra layer of protection, offering comfort and peace of mind to your customers while giving your product a unique market advantage. We are committed to achieving a production pass rate consistently above 97%.

Partnership Built on Two Decades of Trust

For over two decades, Star Harvest has acted as a trusted extension of our clients’ brands. Our “customer-centric” service philosophy means we prioritize stability, security, and partnership:

Design Security: A professional jewelry factory must protect your intellectual property. We implement stringent non-disclosure agreements (NDAs) and robust material batch file management within the jewelry factory to safeguard your original collections, ensuring your designs remain proprietary and secure.

Proactive Problem Solving: Our jewelry factory leverages two decades of knowledge to eliminate manufacturing pain points. We utilize specialized welding techniques and structural modifications within the jewelry factory to address potential weaknesses, preventing issues like high allergy rates that plague less experienced stainless steel jewelry manufacturers.

Commitment to Responsible Sourcing and Values

Our values as a responsible jewelry factory drive our commitment to both product quality and social responsibility. We ensure full transparency, using only eco-friendly plating options within the jewelry factory that adhere to strict European and American REACH compliance standards. When you partner with Star Harvest, you are choosing an expert jewelry factory that leads with integrity and technical sophistication, ensuring the 316L jewelry we produce is the best type of stainless steel on the market for mid-to-large scale brands.