The demand for custom brass jewelry has surged in recent years, driven by trends in personalization and sustainable fashion. For businesses looking to enter this market, understanding how to partner effectively with a brass jewelry manufacturer is key to creating unique, high-quality pieces. This article explores the essential steps involved in making custom brass jewelry, ensuring that brands can deliver outstanding products that resonate with consumers.

Selecting the Right Materials

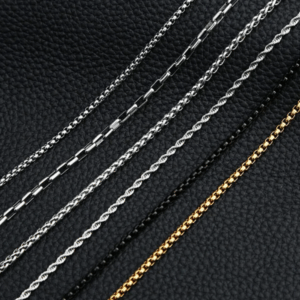

A successful custom brass jewelry project starts with choosing the right materials within a professional jewelry factory. Brass, an alloy of copper and zinc, provides not only durability but also a warm, appealing finish that is perfect for the trendy collections of international brands. When sourcing materials, a high-capacity jewelry factory selects premium brass that is free from harmful elements, ensuring safety, hypoallergenic properties, and longevity in the final product. By focusing on material purity, the jewelry factory guarantees that mid-to-large scale brands receive high-standard foundations for their jewelry lines.

Collaborating with a reputable jewelry factory guarantees that the chosen materials meet rigorous industry standards. A jewelry factory with extensive experience in working with brass can provide critical insights into the best types of alloys and finishes, allowing designers for international brands to create unique looks. Additionally, a professional jewelry factory considers factors such as oxidation resistance and the ability to hold detailed designs, ensuring the end product meets the high expectations of the global market.

Designing Unique Pieces

Once the materials have been selected, the next step is design. Custom brass jewelry should reflect the brand’s identity while catering to current market trends. Engaging in thorough market research can guide designers in crafting pieces that appeal to targeted demographics.

Utilizing advanced design software in the jewelry factory facilitates the creation of detailed 3D models, enabling brand owners to visualize their concepts before moving to mass production. An experienced jewelry factory will often collaborate closely during this stage, providing expert feedback on design feasibility and suggesting structural enhancements. This partnership within the jewelry factory environment is vital for ensuring that the aesthetic intent of fast-growing e-commerce brands aligns perfectly with industrial manufacturing capabilities.

Efficient Production and Quality Control

After finalizing the designs, the next phase is high-efficiency production within the jewelry factory. A reliable jewelry factory typically offers comprehensive OEM (Original Equipment Manufacturer) advantages, streamlining the process from initial concept to the finished product for international retailers. With over 20 years of experience, a premier jewelry factory like Star Harvest implements a sophisticated service system, optimizing production capacity and ensuring every batch meets the strict quality benchmarks required by mid-to-large scale brands.

Elevate Your Offerings with Star Harvest

As you explore the world of custom brass jewelry, partnering with an experienced manufacturer is essential for success. At Star Harvest, we specialize in brass and stainless steel jewelry, leveraging our two decades of expertise to deliver high-quality products and exceptional service. Our commitment to flexible production and market trend insights enables brands to achieve seamless transitions from design concept to product shelf. By collaborating with us, you can confidently create stunning custom brass jewelry that meets the evolving demands of your customers while establishing a strong presence in the market. Let us support your vision and help your brand shine with our quality craftsmanship and innovative solutions.