Fabricating jewelry from stainless steel involves a precise technical journey that transforms raw metal into refined accessories. This process explains why the material offers such durability and a modern aesthetic. For brands considering a partnership with a stainless steel jewelry manufacturer, knowledge of these steps provides insight into production quality and potential. The journey from sheet metal to finished piece relies on specialized equipment and skilled execution.

Material Selection and Initial Design Phase

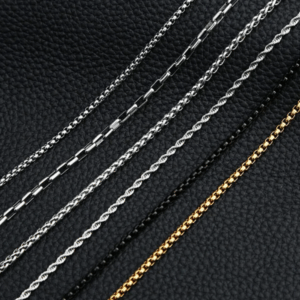

The process begins with grade 316L or 304L stainless steel, chosen for its corrosion resistance and hypoallergenic properties. A stainless steel jewelry manufacturer typically works with sheets, wires, and tubes of this metal. The design phase is critical, especially for custom stainless steel jewelry. Here, technical drawings or digital 3D models are created. These blueprints guide the entire production, specifying every measurement and detail. This stage ensures that both the manufacturer and the client have a unified vision for the final custom stainless steel jewelry collection before any metal is cut.

Fabrication and Formation Techniques

With designs approved, the formation of high-quality jewelry begins in our specialized Jewelry factory. Laser cutting is a common method for achieving intricate patterns from steel sheets with extreme accuracy, a service highly valued by mid-to-large scale brands. For pieces requiring depth or dimension, we employ stamping or CNC molding; stamping uses high-pressure dies ideal for the consistent, high-volume production needs of fast-growing e-commerce jewelry labels. Meanwhile, CNC molding carves the steel into complex, three-dimensional forms. This precision capability allows Star Harvest, as a leading manufacturing partner, to produce everything from simple pendants to structurally complex statement pieces that meet rigorous brand standards.

Finishing: Polishing, Plating, and Quality Control

The final premium appearance of the jewelry is achieved through meticulous finishing at our Jewelry factory. Pieces are polished to create a mirror shine, a satin brush, or a matte texture. For the custom collections of mid-to-large brands, this is the stage where PVD (Physical Vapor Deposition) plating occurs. Unlike traditional silver plating, this advanced technique bonds a durable layer of gold or rose gold to the surface, creating a finish highly resistant to chipping and tarnishing—perfect for fast-growing e-commerce brands that prioritize longevity. Every item undergoes a rigorous final inspection for sharp edges, closure function, and plating consistency, ensuring all custom stainless steel jewelry meets the exact specifications of our global clients.

The creation of stainless steel jewelry is a blend of industrial technology and artistic detail. It is a multi-stage operation that demands expertise in metalwork and finishing. Brands that understand this process can better appreciate the value and durability inherent in each piece. For those seeking a partner to bring their designs to life, Star Harvest operates as a stainless steel jewelry manufacturer equipped to handle both standard and complex custom stainless steel jewelry projects.