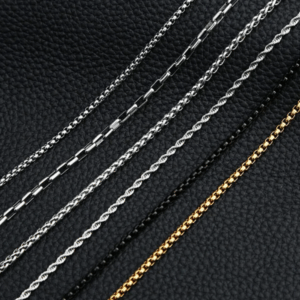

As a professional stainless steel jewelry manufacturer, Star Harvest employs specialized manual texturing techniques to create distinctive surface finishes on stainless steel wire components. These skilled craftsmanship methods allow for the production of unique textures that enhance the visual and tactile qualities of custom stainless steel jewelry, providing brands with exclusive design possibilities that differentiate their collections in the marketplace.

Stable Work Foundation for Precision Texturing

Our manufacturing process begins with establishing a rigorously controlled work environment essential for consistent results. As a professional Jewelry factory, we utilize heavy-duty steel bench blocks securely mounted to vibration-dampened workstations, ensuring precise impact absorption during the texturing process. This high-standard setup allows us to meet the precision requirements of mid-to-large scale brands. The selection of specialized hammers—including polished planishing hammers and cross-peen hammers—enables our craftspeople to execute specific designs for fast-growing e-commerce jewelry labels. Each stainless steel wire component is firmly secured using professional clamping systems, guaranteeing uniform results across large production batches while maintaining the highest safety standards.

Controlled Hammering Techniques for Consistent Patterns

The execution of hammering techniques requires methodical precision and skilled craftsmanship. Our technicians employ consistent, measured strikes along the wire’s surface, rotating the material systematically to achieve uniform texturing on all sides. For pattern creation, we utilize specialized texturing hammers in overlapping, rhythmic motions that produce predictable and repeatable surface designs. This level of control is particularly crucial for brands requiring component consistency across their custom stainless steel jewelry collections, where matching textures must be maintained throughout multiple production runs. Our manufacturing protocols document each technique to ensure design continuity and quality consistency.

Post-Texturing Processing and Quality Verification

Following the texturing process, components undergo comprehensive processing at our Jewelry factory to enhance durability and finish. The hammering operation naturally induces work hardening, which we monitor and control through precise annealing protocols to ensure the structural integrity expected by mid-to-large brands. The textured surfaces then progress through our multi-stage finishing system, concluding with specialized polishing compounds that highlight the patterns while ensuring comfortable wearability. Each component undergoes rigorous quality verification to confirm texture consistency and dimensional accuracy, providing fast-growing e-commerce brands with the reliable quality they need to maintain a strong market reputation.

Mastering manual texturing techniques represents a significant value enhancement in stainless steel jewelry manufacturing. These craftsmanship methods transform standard wire into distinctive components that elevate brand collections through unique tactile experiences. At Star Harvest, our capabilities as an experienced stainless steel jewelry manufacturer include extensive expertise in these specialized texturing processes, enabling us to produce exceptional custom stainless steel jewelry that reflects brand identity and quality expectations. We partner with brands to develop signature texturing treatments that distinguish their products in competitive markets.