Metal quality is a critical factor for any jewelry designer working with stainless steel. As a leading Jewelry factory, Star Harvest understands that for mid-to-large scale brands seeking exceptional durability, knowing how to professionally harden stainless steel jewelry wire can make a significant difference in both large-scale production and final product quality. For fast-growing e-commerce jewelry labels, mastering these techniques through a reliable manufacturing partner ensures that each piece performs as expected while maintaining its premium aesthetic appeal and structural resilience.

Mechanical Work Hardening

One effective method to increase the strength of stainless steel jewelry wire is mechanical work hardening. This process involves carefully bending, twisting, or rolling the wire to improve its tensile strength without altering its composition. Each cycle of deformation increases the density of the metal’s crystal structure, which enhances rigidity. Jewelry creators who rely on custom stainless steel jewelry frequently use work hardening to maintain precise shapes and support intricate designs. When paired with consistent monitoring, this approach allows manufacturers to achieve the perfect balance between flexibility and durability.

Heat Treatment Considerations

Heat treatment is a specialized approach used by our Jewelry factory to modify the hardness of stainless steel jewelry wire with precise control. Stainless steel’s properties are carefully altered through controlled heating and cooling, which optimizes workability and resistance to bending for mid-to-large brands. At Star Harvest, we often combine heat treatment with mechanical techniques to reinforce the wire for demanding, complex designs. By mastering these industrial processes, we help fast-growing e-commerce brands create custom stainless steel jewelry that retains its form, endures daily wear, and allows for detailed finishing without ever compromising the material’s inherent strength.

Choosing the Right Stainless Steel

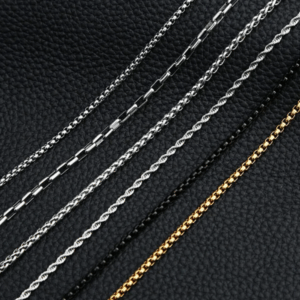

The type of stainless steel selected plays a crucial role in how effectively the wire can be hardened. Variations in alloy composition, such as the percentage of chromium and nickel, influence malleability, corrosion resistance, and overall performance. Jewelry makers sourcing materials from a stainless steel jewelry manufacturer must ensure that the wire meets industry standards for hardness and flexibility. High-quality wire simplifies the hardening process and minimizes the risk of breakage during fabrication, leading to more reliable and consistent results for custom stainless steel jewelry designs.

Achieving Durable, Long-Lasting Jewelry

Hardened stainless steel jewelry wire provides a foundation for robust and appealing pieces. By applying mechanical work hardening, considering heat treatment, and selecting the proper stainless steel, manufacturers and designers can ensure that their products combine resilience with aesthetic precision. These techniques allow custom stainless steel jewelry to maintain its shape, withstand daily wear, and support complex patterns. Star Harvest consistently implements these strategies in collaboration with our partners to deliver high-quality stainless steel pieces that meet client expectations for performance and style.