With nearly 20 years of experience in copper and stainless steel jewelry manufacturing, we empower brand iteration with our full-chain precision process capabilities: from millimeter-level precision mold development, multi-material composite casting, to zero-defect vacuum plating and anti-allergic coating technology, to laser engraving, micro-stone inlay and other complex processes – relying on 3000+ mature process databases and modular production systems to ensure the perfect realization of your design from drawings to mass production

Making a mold is the first step in jewelry manufacturing, which directly affects product accuracy and subsequent production efficiency. We use highly elastic silicone mold technology to perfectly replicate complex design details and provide stable and durable production molds for brass and stainless steel jewelry.

Wax injection is a key step to inject liquid wax into the rubber mold to form a high-precision wax mold. This process directly affects the detail restoration and surface finish of the finished jewelry , and is suitable for the precision casting needs of copper and stainless steel jewelry.

Waxing is a key step in fine finishing of wax models to ensure the surface finish and structural integrity of the final jewelry. This process is suitable for mass production of high-precision copper and stainless steel jewelry, and can handle complex designs such as hollowing, fine lines, and curved surfaces.

Treeing (also known as “wax tree assembly”) is a key step in splicing the trimmed wax model to the wax rod according to the requirements of the casting system. This process directly affects the metal fluidity and yield rate during casting, and is especially suitable for the mass production of copper and stainless steel jewelry.

Plastering (plaster mold making) is the core process of fixing the completed wax mold in a special gypsum slurry to form a high-temperature resistant casting mold. This process directly determines the metal liquid filling effect and the surface accuracy of the final product, and is suitable for the precision casting needs of copper and stainless steel jewelry.

Losing wax is a key step in removing the wax core from the plaster mold through heat treatment to form a complete cavity. This process directly affects the product forming accuracy and surface finish, and is the core process of lost wax casting of copper/stainless steel jewelry.

Sand casting is a small and medium-sized jewelry manufacturing process that uses sand molds to form jewelry. It is suitable for mass production of copper-based alloy and stainless steel jewelry. This process has low cost and fast mold turnover, and is particularly suitable for products with rugged or retro styles.

Dewaxing is a key step in lost wax casting, which directly affects the surface quality and detail restoration of the casting. The wax pattern is removed through precise temperature control to provide a clean cavity for subsequent metal pouring.

Making a mold is the first step in jewelry manufacturing, which directly affects product accuracy and subsequent production efficiency. We use highly elastic silicone mold technology to perfectly replicate complex design details and provide stable and durable production molds for brass and stainless steel jewelry.

The assembly process is the final stage of jewelry production, which directly affects the integrity and wearing comfort of the finished product. This process is suitable for key processes such as component connection, clasping, and assembly after polishing of copper/stainless steel jewelry to ensure that the product meets the quality standards of the brand.

Brazing & Soldering is a key process for connecting metal parts in jewelry manufacturing, which directly affects the firmness and appearance integrity of the product. It is suitable for precision welding of copper and stainless steel jewelry to ensure that there is no cold solder joint, discoloration or solder overflow at the joint.

Forming & Shaping is a key process to ensure that the finished jewelry meets the designed size and is comfortable to wear. It is suitable for curvature adjustment, structural correction and surface optimization of copper and stainless steel jewelry to avoid the risk of breakage caused by deformation or stress concentration.

Mold Polishing & Finishing is a fine processing step in jewelry manufacturing. It is responsible for removing burrs, pores and joint lines after mold casting, improving surface finish and shape accuracy, and ensuring that the product meets design requirements and subsequent processing needs.

Grinding & Lapping is a key process for precision finishing of metal jewelry surfaces, eliminating tool marks, oxide layers and microscopic bumps, and providing a qualified base surface for subsequent polishing/electroplating. It is mainly used for batching , welding and structural interfaces of copper and stainless steel materials.

Copper plating is a process of electroplating a copper layer on the surface of a jewelry substrate (stainless steel/zinc alloy/silver). It is mainly used for:

The type printing process uses laser engraving or mechanical stamping technology to form a clear and permanent mark on the surface of jewelry, meeting the needs of brand logo, metal material mark (such as 925 silver) and compliance certification mark. This process supports 0.1mm high-precision engraving and is suitable for common jewelry materials such as copper and stainless steel.

Polishing is used to improve the surface finish and gloss of jewelry, remove processing marks (such as turning marks, welding points), and make the product present different effects such as mirror, matte or brushed. This process uses a combination of mechanical and chemical methods, suitable for copper, stainless steel and other metals, and meets the appearance quality standards of the European and American markets.

The electroplating process forms a metal protective layer on the surface of jewelry through electrolytic deposition, achieving anti-oxidation, wear resistance and color customization (such as platinum, rose gold, gun black, etc. ). This process complies with RoHS/REACH environmental standards, is suitable for copper and stainless steel substrates, and can meet the stringent requirements of the European and American markets for coating thickness (0.5-5μm) and corrosion resistance.

The packaging process directly affects the product transportation safety, brand display effect and customer unpacking experience. We provide packaging solutions that meet European and American environmental standards (FSC certified paper, biodegradable materials), adapting to different product types (single piece/set), logistics needs (moisture-proof air/sea transportation) and brand customization requirements (LOGO printing, structural innovation).

Each product conveys your brand concept and stands out in the fierce competition in the jewelry market. We provide cost-effective Private Label jewelry customization services. From logo engraving, packaging design to material and craft selection, the whole process is accurately matched according to your brand tone. Years of experience in the jewelry market industry ensure that the products meet international environmental standards and market demand, helping you quickly create a differentiated brand product line.

From material selection, casting, assembly to electroplating, polishing and packaging, we have set up strict quality inspection checkpoints at more than 60 key nodes, covering material composition and environmental testing (such as nickel release, lead content), physical performance testing (salt spray anti-discoloration, torque, drop, snap-fit function) and process inspection (electroplating layer thickness adhesion, polishing uniformity, welding strength) to ensure that each batch of products meets your design specifications and safety standards, and achieves stable quality delivery.

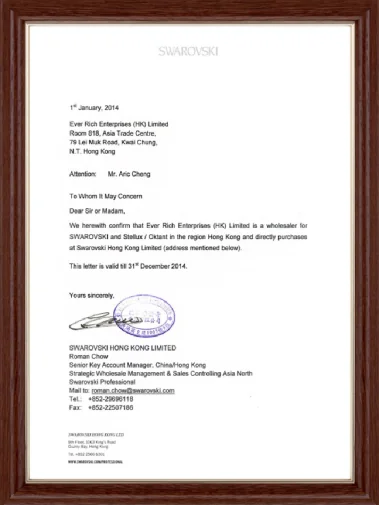

As an officially authorized partner of Swarovski crystal, we ensure that every crystal used in your custom jewelry is authentic and traceable, and is guaranteed by Swarovski’s strict quality and color standards. We provide you with reliable raw material support and avoid disputes over imitations. At the same time, we guarantee a stable and sustainable supply, which is a solid backing for you to create exquisite jewelry with brand added value and consumer trust.

We hold a valid BSCI factory inspection report and strictly follow its global social responsibility standards for production, ensuring that the custom jewelry you cooperate with is not only of high quality, but also in line with internationally recognized ethical standards, avoiding supply chain risks for your brand and providing a strong social responsibility endorsement.

We are ISO 9001:2015 certified, ensuring that the entire process from raw material procurement, production process to final delivery is strictly controlled, ensuring that the quality of your customized jewelry is consistent and stable, meeting your specifications, systematically reducing the risk of defects and improving supply chain efficiency, providing your brand with a more reliable and predictable long-term production partner.

We hold SA8000 social responsibility international standard certification and strictly follow internationally recognized labor protection, health and safety, prohibition of forced and child labor and other guidelines for production, ensuring the ethical compliance of your customized jewelry supply chain, significantly reducing human rights risks for your brand and providing strong ethical manufacturing proof, which is an indispensable compliance guarantee for you to build a responsible brand.

We focus on providing customers with high-quality customized jewelry solutions. Our products cover a variety of materials such as brass and stainless steel to meet the needs of different brands and market positioning. Whether you pursue classic elegance or modern fashion, we can provide a customized solution that perfectly meets your expectations.