Precision-Engineered Jewelry Casting for Global Brands

Supporting your fastest-growing collections with zero-porosity standards, ISO-certified facilities, and industrial-grade scalability.

Why Your Current Casting Reject Rate is Killing Your Margin

In large-scale jewelry production, poor casting is more than a defect—it is a critical bottleneck. High reject rates lead to wasted raw materials, delayed product launches, and compromised brand reputation.

Most high-volume brands struggle with five core casting defects that Star Harvest eliminates through our SH-P Quality System:

Shrinkage & Porosity

Irregular voids caused by improper sprue design or inadequate metal feed during solidification.

Gas Porosity

Tiny, smooth-walled bubbles trapped within the metal, often due to improper vacuum levels or contaminated alloys.

Inclusions (Slag)

Non-metallic particles or oxides embedded in the surface, usually resulting from crucible contamination or low-strength investment.

Thermal Cracks

Fractures caused by premature quenching or “pull-rod effects” during the cooling phase.

Deformation

Dimensional inaccuracies or warping due to wax mold instability or uneven cooling rates.

Understanding the technical trade-offs between methods is vital for maintaining a consistent custom jewelry casting service.

While multiple techniques exist, Star Harvest specializes in high-precision lost wax casting for its superior detail retention.

Precision Engineering at Every Step

Star Harvest doesn’t just “pour metal.” We engineer every stage of the wax mold casting jewelry process to ensure that the first unit is identical to the 10,000th.

High-Elasticity Mold Making

We utilize high-elasticity silicone mold technology to replicate complex design details. Before production, our engineering team performs a tolerance analysis at the 3D design stage, ensuring a design restoration accuracy of ±0.03mm.

Digital Wax Tree Assembly

Known internally as “Treeing,” this step determines metal fluidity. We utilize an industrial 3D scanner to cross-verify wax embryos against original CAD files. Any wax mold with air bubbles or deformation is rejected before the tree is even built.

Vacuum-Assisted Casting

By utilizing professional vacuum casting machinery, we remove air from the investment mold to create a negative pressure environment. This ensures the molten metal fills even the most microscopic filigree details while preventing sub-surface gas porosity.

Post-Casting Refining & Cleaning

After the “Get Off the Tree” phase, components undergo ultrasonic cleaning and grinding to remove oxidation layers. We ensure all connection points are seamless, with no cold solder joints or overflow.

Final Technical Inspection

Every batch undergoes functional testing, including 500-cycle clasp durability tests and 15-50N tension tests for chains and components.

Quality Guarded at Every Micron

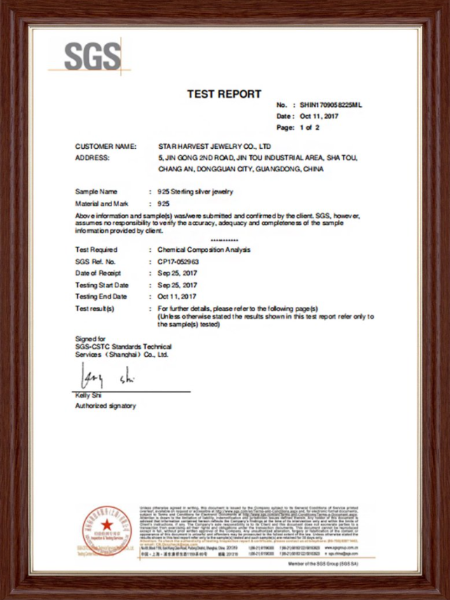

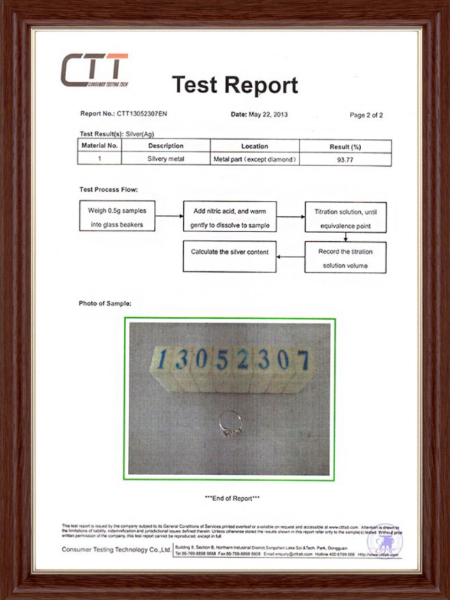

At Star Harvest, quality is a verifiable data point, not a promise. Our jewelry casting services are backed by a laboratory-grade inspection protocol.

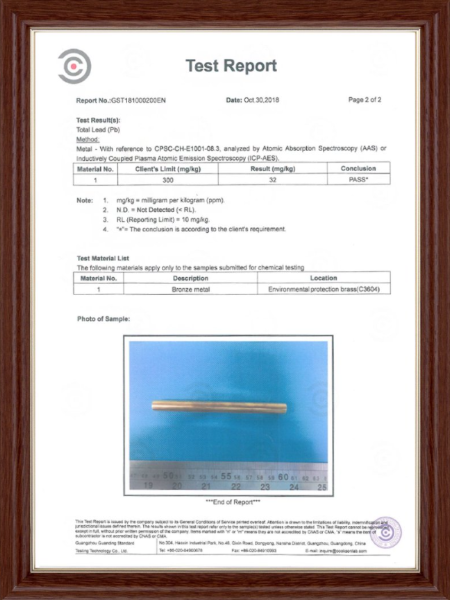

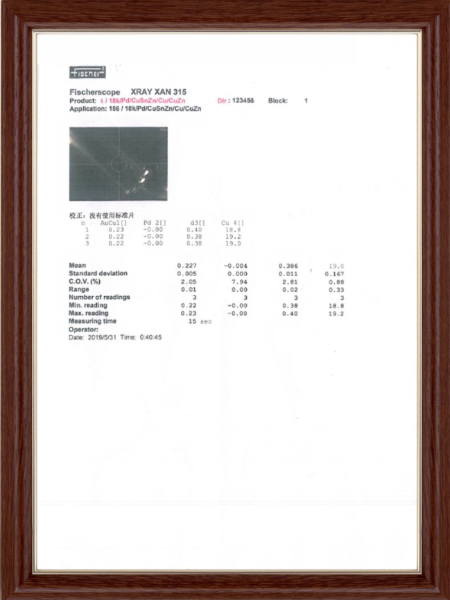

We implement a triple locking mechanism. Every batch of brass or stainless steel undergoes 100% spectrum screening, 100% alloy ratio verification, and 100% environmental limit pre-screening. We utilize XRF (X-Ray Fluorescence) technology to ensure purity ≥99.9% and full compliance with thresholds like REACH, RoHS, and California 65 standards.

Before casting, wax embryos are scanned and compared to CAD files. We maintain a strict tolerance control of ±0.15mm for overall dimensions, ensuring the final piece matches your creative vision perfectly.

To ensure structural integrity post-casting, we perform hourly random screenings. Our technicians utilize precision calipers and digital projectors to inspect critical areas like weld strength and link closures, effectively eliminating sand holes and structural vulnerabilities.

With a database of over 3,000 mature processes, our IPQC (In-Process Quality Control) monitors over 60 critical nodes. This results in a final qualified rate of over 98% for mass production orders.

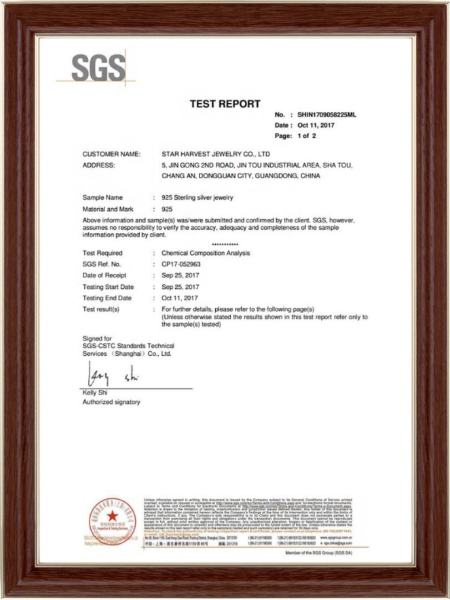

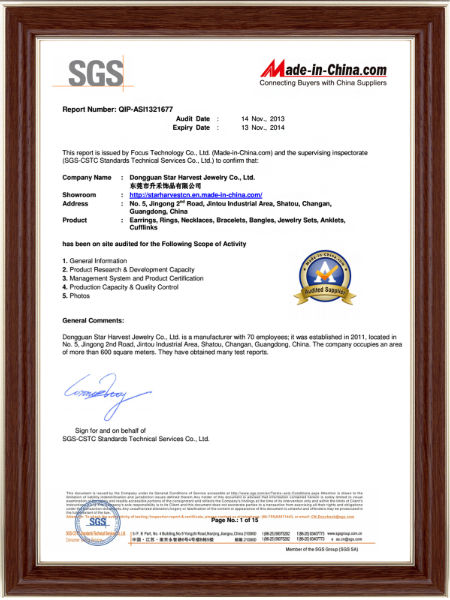

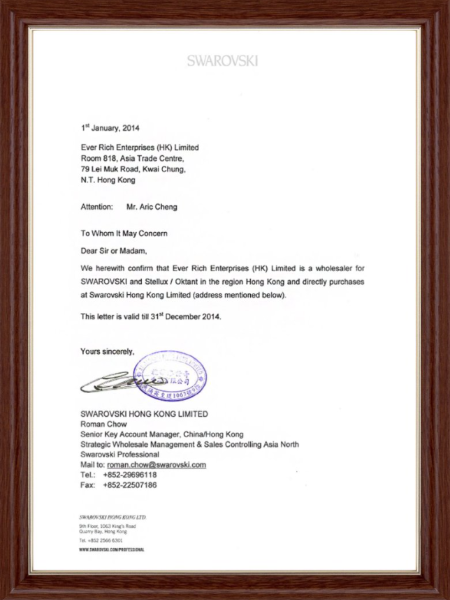

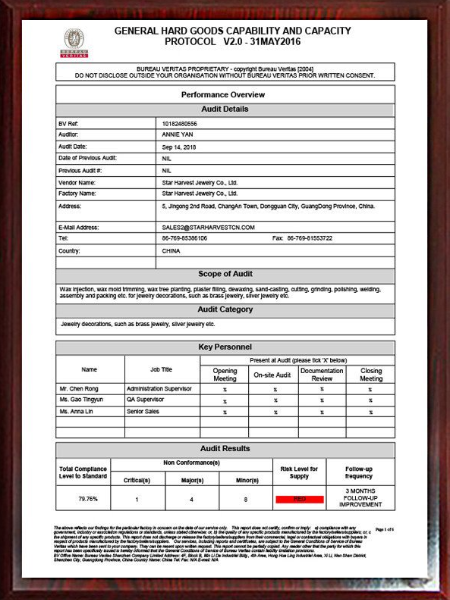

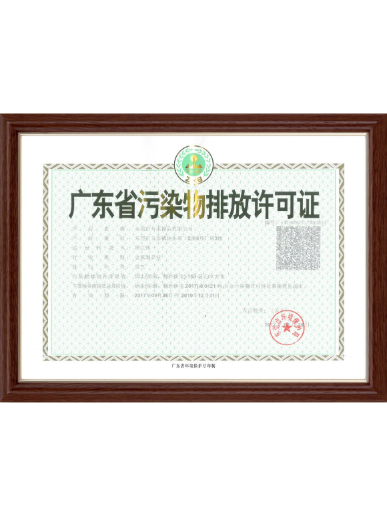

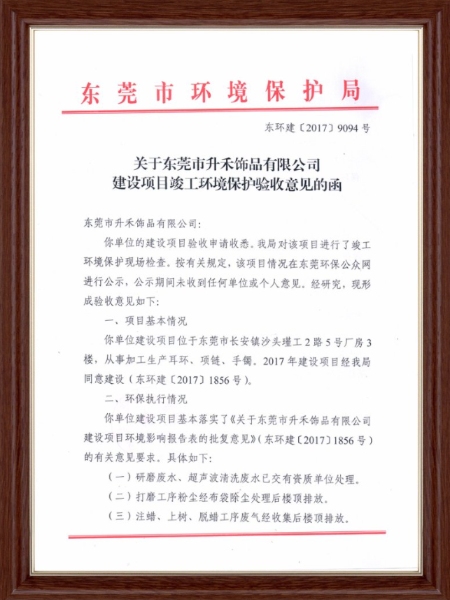

Star Harvest Certificates

Star Harvest is more than a factory; we are an ISO 9001 and BSCI-certified partner.

Our facilities are regularly audited to ensure ethical production and technical excellence.