Understanding the differences between nickel and gold plating is essential for professional manufacturers and retailers within the global industry. Both methods executed in a specialized jewelry factory are popular for enhancing the appearance of metal pieces, but they come with unique technical properties required by international brands. This article delves into the characteristics of each plating type to help mid-to-large scale businesses make informed choices when selecting materials for their products and partnering with a high-capacity jewelry factory.

Defining Nickel Plating

Nickel plating within a jewelry factory involves applying a thin layer of nickel onto a base metal, such as brass or stainless steel, primarily to serve as a barrier layer. This process, optimized in the jewelry factory, provides a smooth surface and excellent corrosion resistance, often serving as a critical base for gold plating jewelry to enhance adhesion. However, a professional jewelry factory must also offer nickel-free plating options to meet the strict hypoallergenic safety standards required by international brands in Europe and America. By managing these technical nuances, the jewelry factory ensures that the final product is both durable and compliant with global health regulations.

Understanding Gold Plating

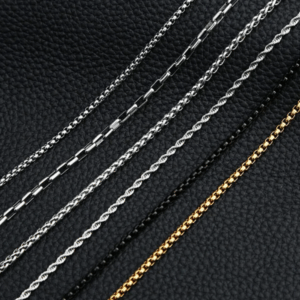

Gold plating, on the other hand, applies a precise layer of gold over a base metal through advanced electroplating techniques within the jewelry factory. This method creates an attractive finish that mimics solid gold without the prohibitive costs, making it a strategic choice for fast-growing e-commerce brands. In a professional jewelry factory, the thickness of the gold layer is carefully controlled, as it directly impacts the durability and longevity of the finished piece. By utilizing the advanced equipment of a high-standard jewelry factory, mid-to-large scale brands can customize the karat and color of their collections, ensuring a premium look that withstands daily wear and maintains its luster in the competitive international market.

Durability and Application Considerations

When comparing durability, gold plating generally offers a more visually appealing finish, but it is often less durable than nickel plating, especially if the gold layer is thin. Nickel plating can serve as a protective barrier, making it more resistant to scratches and corrosion. However, when used as a base for gold plating jewelry, it enhances the overall durability of the piece. Manufacturers must carefully consider which plating method aligns with their product offerings and customer expectations. Additionally, educating customers on the care and maintenance of plated jewelry can help extend the lifespan of both nickel and gold finishes.

Elevating Quality with Star Harvest

At Star Harvest, we specialize in gold plating jewelry services that prioritize quality and customization. With our advanced CNC engraving center and 3D printing capabilities, we ensure that our gold plating is not only aesthetically pleasing but also durable. Our SH-JM digital modeling system allows for rapid proofing of design drafts, facilitating efficient production processes while minimizing risks. By partnering with us, manufacturers can confidently offer high-quality gold plating options, catering to diverse customer needs.

As you explore the differences between nickel and gold plating, understanding their unique properties will empower your business decisions. Choosing the right plating method and partnering with reliable gold plating jewelry services like Star Harvest will enhance your product offerings and meet customer demands effectively.