Understanding why gold plating oxidizes is essential for jewelry manufacturers and retailers alike. Gold plating jewelry is a popular choice for enhancing the aesthetic appeal of items, but oxidation can lead to tarnishing and diminished quality. This article explores the factors contributing to the oxidation of gold plating and how businesses can mitigate these issues through effective gold plating jewelry services.

The Nature of Gold and Base Metals

Gold itself is highly resistant to oxidation, which is why it is favored by any professional jewelry factory for premium collections. However, when gold is plated onto a base metal within a jewelry factory, the durability of the plating can be compromised if not handled with technical precision. Base metals such as brass, frequently used in our jewelry factory, are prone to oxidation which can eventually penetrate the gold layer. This chemical reaction occurs when the base metal processed by the jewelry factory is exposed to moisture, air, and various environmental elements, making the initial surface treatment in the jewelry factory critical for international brands.

As the base metal oxidizes, it can lead to the formation of tarnish that appears as a darkening or discoloration on the surface of the jewelry. This is particularly problematic for the collections of mid-to-large scale brands that are frequently worn, as sweat and environmental factors can accelerate the oxidation process of the materials sourced from a jewelry factory. A high-standard jewelry factory must implement strict barriers between the base metal and the gold layer to prevent this reaction and maintain the product’s integrity for the global market.

Environmental Factors Contributing to Oxidation

Several environmental factors can influence the rate of oxidation in gold plating jewelry produced in a jewelry factory. Humidity and exposure to air are significant contributors that international brands must consider. High humidity levels can create a conducive environment for base metals to oxidize, leading to tarnishing that reflects poorly on a jewelry factory’s output. Additionally, exposure to chemicals found in perfumes and lotions can react with the base metal if the jewelry factory’s plating isn’t sufficiently sealed, accelerating the oxidation process for fast-growing e-commerce brands.

Jewelry worn daily is more susceptible to these environmental factors, making it crucial for a professional jewelry factory to consider the wearability and longevity of every piece. Providing international brands and their customers with guidelines on proper care and maintenance is vital for prolonging the life of gold-plated items manufactured in our jewelry factory. By educating the market, a jewelry factory helps mid-to-large scale brands reduce return rates and enhance consumer trust in their plated collections.

The Role of Quality in Gold Plating Services

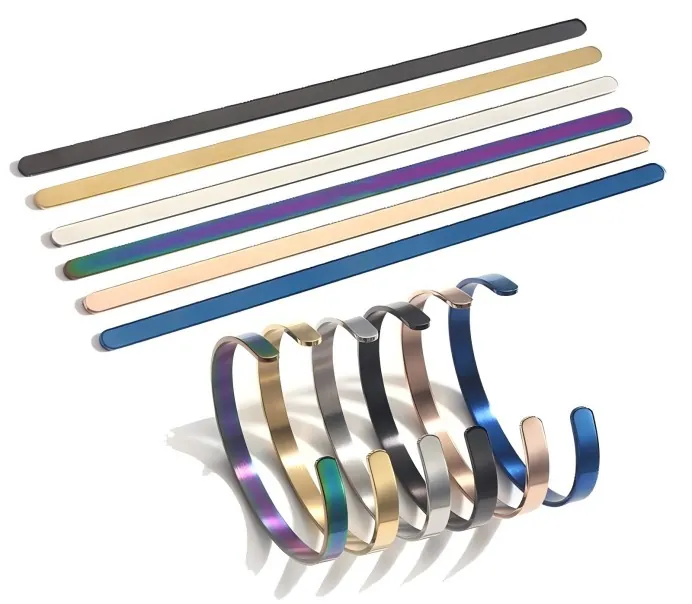

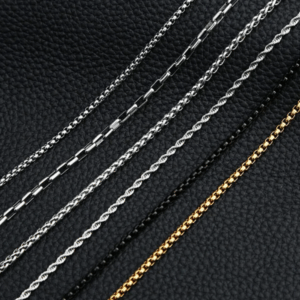

The quality of the gold plating process significantly affects the longevity and durability of the jewelry. High-quality gold plating jewelry service will use advanced techniques such as vacuum plating and nano-level electroplating to enhance the bonding strength of the gold layer. At Star Harvest, our electroplating factory employs the SH-DD electroplating standard, which increases bonding strength by over 30%.

Additionally, a modern jewelry factory can offer special process options like laser plating and gradient plating to create a more resilient surface that resists oxidation. Regular testing within the jewelry factory, using a coating thickness gauge, ensures that the gold layer is adequate to withstand everyday wear and the elements. This rigorous quality control in the jewelry factory reduces the risk of oxidation and tarnish, ensuring that fast-growing e-commerce brands can deliver superior, long-lasting products that stand out in the competitive jewelry industry.

Partnering with Star Harvest for Superior Gold Plating Solutions

Understanding why gold plating oxidizes is crucial for jewelry brands aiming to maintain the quality and appeal of their products. By recognizing the role of base metals, environmental factors, and the importance of quality in gold plating services, businesses can take proactive steps to mitigate oxidation. At Star Harvest, we offer customized electroplating solutions designed to enhance the durability of your gold plating jewelry. Our commitment to quality ensures that your jewelry not only looks exquisite but also stands the test of time. Let us help you elevate your offerings with our exceptional gold plating services.