As the Australian jewellery market evolves, demand for high-quality women’s stainless steel rings is surging. However, success demands more than just inventory; it requires strict adherence to quality and ethical standards championed by bodies like the JAA.

Consequently, selecting the right OEM has become a strategic imperative.This guide explores the essential criteria Australian jewellers must evaluate to secure a competitive edge in the stainless steel wedding rings for women and fashion ring sectors.

Key Factors for Evaluation

1. Core Product Quality and Health Safety Standards

For Australian brands, compliance with health and safety standards is non-negotiable. The Australian Consumer Law (ACL) and industry expectations require products to be safe for prolonged contact with skin. When evaluating an OEM, the first checkpoint is the raw material.

- Mandatory Health and Safety Certifications: Top-tier OEMs must utilise medical-grade, nickel-free stainless steel, specifically 316L or 304 grades. This is crucial for stainless steel engagement rings for women, which are intended for daily, long-term wear.

- Nickel release is a common cause of contact dermatitis, and Australian consumers are increasingly educated about “hypoallergenic” claims. An OEM must provide verifiable test reports verifying their steel is free from hazardous heavy metals and compliant with international safety standards such as RoHS and REACH.

- Durability and Surface Treatment Technologies: The perceived value of stainless steel jewellery often hinges on its finish. To capture the market for stainless steel rings for women, OEMs must employ Physical Vapour Deposition (PVD) coating rather than traditional electroplating. PVD technology ensures a bond at the molecular level, creating rose and yellow gold finishes that are exceptionally resistant to fading.

- Salt Spray Testing: A reliable OEM will not just claim durability; they will quantify it. Look for manufacturers who conduct rigorous salt spray testing (often up to 1,000 hours) to verify anti-corrosion properties. This is particularly relevant for the Australian market, where coastal living exposes jewellery to humid, saline environments.

- Surgical-Grade Polishing: The tactile experience is equally important. The ring’s surface should undergo multiple stages of polishing to achieve a mirror-like smoothness akin to surgical steel. This ensures comfort for everyday wear, preventing the irritation that can occur with lower-quality, rougher finishes.

2. Adapting to Market Trends and Customisation Capabilities

The modern Australian jewellery market is driven by customisation. Generation Z and Millennial consumers are moving away from mass-produced uniformity in favour of personalised storytelling.

- Support for Personalisation and Custom Design: A competent OEM acts as an extension of your design team. Whether it is stainless steel wedding rings for women with intricate engravings or modular rings that allow for stacking, the manufacturer must support complex customisation. This goes beyond simple logo etching. Leading OEMs offer comprehensive services ranging from initial concept 3D rendering to precision mould development.

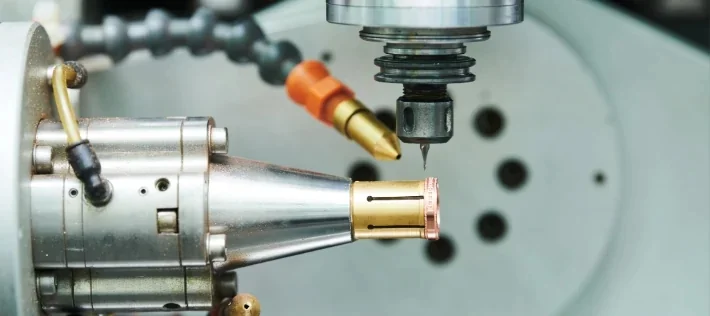

- Technological Integration: Look for partners utilising advanced CNC engraving centres and German-imported 3D printing equipment. These technologies allow for the creation of high-precision moulds with tolerances as tight as 0.02mm. This capability is vital for executing complex designs, such as hollow filigree or relief patterns, which are increasingly popular in the “affordable luxury” segment. The ability to translate a unique brand concept into a physical sample without losing fidelity is what separates a generic supplier from a strategic partner.

3. Digital Operations and Agile Supply Chain

In an era of fast fashion and rapid trend cycles, supply chain efficiency is as critical as product quality. Australian e-commerce brands cannot afford months-long lead times that result in missed seasonal opportunities.

- Rapid Prototyping and Production Cycles: Speed to market is a key differentiator. Advanced OEMs leverage digital modelling systems to shorten sample production times significantly. Some can deliver rapid proofing of design drafts within 24 hours and physical samples in under a week. This agility allows brands to test new designs for stainless steel rings for women in the market quickly before committing to mass production.

- Supply Chain Flexibility and Transparency: The rigid Minimum Order Quantities (MOQs) of the past are incompatible with modern inventory management. Superior OEMs offer flexible MOQs (often starting at 200 pieces), enabling brands to diversify their SKUs without overstocking.

Furthermore, the integration of comprehensive MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) systems is a hallmark of a mature manufacturer. These systems provide real-time visibility into order status, quality control data, and production milestones, ensuring that Australian clients can manage their supply chain with transparency and confidence.

Star Harvest: Elevating Quality Standards for Australian Brands

For Australian jewellery brands seeking a partner that embodies these high standards, Star Harvest stands out as a premier choice. As a specialised OEM/ODM manufacturer, Star Harvest has tailored its operations to meet the rigorous demands of medium to large-scale international brands.

Star Harvest distinguishes itself with a commitment to medical-grade, nickel-free stainless steel, ensuring every piece meets the strict health safety requirements of the Australian market.

Our mastery of PVD coating technology is evidenced by industry-leading durability stats, including passing 1,000-hour salt spray tests and boasting colour retention for over three years. This makes us an ideal partner for producing high-end stainless steel rings for women gold that withstand the Australian climate.

Beyond material excellence, Star Harvest offers a robust digital manufacturing ecosystem. Our facility is equipped with state-of-the-art 3D printing and CNC technology, supporting deep customisation and rapid prototyping. Our “Hot Jewellery Quick Response System,” underpinned by integrated MES+ERP management, ensures flexible MOQs and transparent production tracking.

By choosing Star Harvest, Australian jewellers gain a partner capable of delivering the precision, compliance, and agility needed to succeed in a competitive market.