The United Kingdom’s jewellery market is undergoing a profound transformation. We are witnessing a distinct shift where the dichotomy between “mass-produced” and “bespoke delivery” is becoming increasingly blurred. Driven by an educated consumer base that values narrative, intricate geometry, and personalization, market trends are moving away from simplistic stamped designs toward complex, emotionally resonant pieces.

To meet this demand, successful brands are revisiting and optimizing one of the oldest manufacturing techniques in existence: lost wax jewellery casting. While the fundamental principles remain rooted in history, the modern application of this process is a marvel of engineering and digital integration. It is no longer just a method for art; it is a strategic manufacturing solution that underpins high-quality production for brands that value detail, repeatability, and design freedom.

For UK brands seeking to strengthen their position in the customised or studio-crafted jewellery segment, understanding how to leverage lost-wax casting is essential for achieving scalable production while maintaining bespoke, artisan-level quality.

Understanding the Lost Wax Casting Process in Jewellery

To the uninitiated, casting may seem like a simple pouring of metal. However, for the strategic manufacturing partner, lost wax casting for jewellery making is a rigorous science governed by thermodynamics, fluid dynamics, and material chemistry. It is a multi-stage process where every variable impacts the final yield and metal integrity.

The Critical Stages of Production

- Master Model and Wax Pattern:The process begins with the creation of a master model, which defines all the final details and proportions of the jewellery piece. This master is commonly produced as a physical sample to ensure the level of precision and surface quality required for high-end custom work. Once the master model is approved, a rubber or silicone mould is made from it, enabling consistent wax patterns to be reproduced for casting.

- “Tree”:This is a critical engineering step. Wax patterns are attached to a central wax stem to form a “tree.” The arrangement is not arbitrary; the gating system must be optimized to ensure directional solidification. The goal is to ensure the metal freezes from the outermost details back toward the main sprue, preventing shrinkage porosity.

- Investment:The assembled wax tree is positioned inside a metal flask and filled with investment plaster. As the plaster sets, it forms a heat-resistant ceramic mould that will later hold the molten metal. This step is straightforward but critical, as the quality of the investment directly affects surface detail and casting accuracy.

- The Burnout Cycle:The flask is heated in a kiln to remove the wax—hence “lost wax.” This is a delicate phase. Residual carbon from incomplete combustion can lead to gas porosity. Modern cycles are optimized to ensure complete burnout, preventing the formation of gases such as CO and SO2 (from gypsum decomposition) that can damage the metal.

- Metal Casting:Molten metal is introduced into the cavity, often using vacuum or centrifugal force to ensure complete fill. Temperature control is paramount here; the melt must be superheated (often 100 K above liquidus) to ensure flow, but not so hot that it degrades the investment mould.

- Quenching:After casting, the pieces are allowed to cool under controlled conditions—typically 10–15 minutes—to avoid thermal shock or brittleness. Proper cooling ensures that the metal retains its structural integrity and prevents microscopic cracks that could affect durability or finish.

- Cleaning:Once cooled, the investment mould is carefully removed, and the individual pieces are separated from the wax tree. Residual plaster and sprues are meticulously cleaned away, and delicate details are inspected to ensure no damage occurred during casting. This stage is critical for preserving fine textures and preparing the pieces for polishing.

- Finishing:The cast pieces are ground, polished, and refined to meet the final design specifications, ensuring that all intricate details are preserved. Additional hand-finishing techniques, such as engraving, texturing, or subtle surface treatments, may be applied to achieve the intended artisan quality and visual depth.

Why Lost Wax Jewellery Casting Remains a Core Technique

Despite the advent of various manufacturing technologies, lost wax jewellery casting remains the backbone of the industry. For brands looking to scale, it offers specific strategic advantages that alternative methods, such as die-striking or direct metal printing, cannot currently match.

High Design Fidelity & Complex Geometry

The primary advantage lies in the ability to reproduce complex undercuts, organic curves, and intricate filigree that are impossible with subtractive manufacturing. With the integration of 3D printing into the casting workflow, brands can achieve designs with unlimited freedom. This is particularly vital for the UK market, where demand is high for unique, “storytelling” pieces that feature elaborate details.

Production Scalability Without Losing Artisanal Detail

Scalability in jewellery often comes at the cost of detail. However, lost wax casting allows for high repeatability. Once a master mould or digital file is perfected, it can be reproduced thousands of times with identical precision. Innovative wax tree assembly techniques have reduced cycle times by up to 60% in some facilities, allowing brands to ramp up inventory for peak seasons like Christmas or Valentine’s Day without compromising the finishing aesthetic.

Material Versatility

The process is agnostic to the metal used, though the technique varies. It supports everything from brass, bronze for fashion lines or more. For brands operating across different price points, lost wax jewellery casting provides a unified production methodology tailored to the specific material selection.

You Might Also Want to Know

1. What causes porosity in jewelry casting?

Porosity (tiny holes in the metal) is primarily caused by trapped gas bubbles that fail to escape the mold or shrinkage as the metal cools unevenly. It is prevented by using proper gating systems and vacuum casting methods.

2. Can any wax be used for lost wax casting?

No. The process requires specialized industrial injection wax or carving wax. These are formulated to burn out completely clean without leaving ash residue that would ruin the surface detail of the jewelry. Eco-conscious manufacturers use recyclable wax.

3. How accurate is lost wax casting?

It is extremely high-precision, capable of replicating textures as fine as a fingerprint.

Key Considerations for UK Brands Selecting Manufacturing Partners

For a procurement director or brand manager, selecting a manufacturing partner is ultimately about ensuring that fine, customised details can be reproduced consistently at scale. Price per gram becomes secondary when the real differentiator is the partner’s process capability—how well they control mould-making, sprue design, casting stability, and finishing workflows to deliver intricate pieces repeatedly without loss of detail. Evaluating a manufacturer’s technical depth is therefore essential to achieving both precision and reliable batch production.

Precision Standards and Defect Control

Defects such as shrinkage and porosity directly undermine profitability, leading to rework, weak stone settings, and customer returns. In jewellery casting, preventing these defects relies on optimising the wax tree layout, designing appropriate sprues and gating, and using controlled casting methods such as vacuum or centrifugal casting. A competent manufacturing partner will understand how to balance metal flow, cooling rate, and sprue placement to minimise shrinkage porosity—especially in thicker or more sculptural designs. Brands should ask potential partners how they engineer their trees and gating systems to ensure stable, defect-free results.

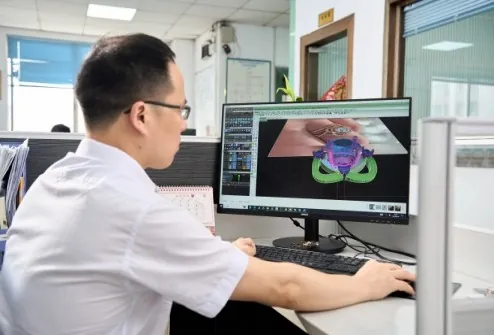

Integration With Digital Workflows (CAD-to-Cast)

Speed to market is a competitive advantage. Brands should look for partners who provide an integrated CAD-to-Cast workflow, allowing digital design files to move smoothly through modelling, sample-making, and casting within the same facility. Consolidating these steps under one roof reduces coordination delays and minimises the need to ship samples back and forth during prototyping—significantly lowering both turnaround time and the environmental impact of repeated logistics. Digital tools, including in-house printing when appropriate, simply support this streamlined process rather than define it.

Sustainability and Material Traceability

Sustainability is no longer optional in the UK market; it is a license to operate. Consumers demand ethical sourcing. Using recycled metals, like silver, brass and stainless steel, is a key strategy. For instance, recycled silver has a carbon footprint 10 times lower than mined silver. Brands should prioritize manufacturers who are members of the Responsible Jewellery Council (RJC) and can provide transparency regarding the use of recycled alloys and the management of scrap metal.

Partnering for Growth: Star Harvest

For brands seeking to navigate these complexities, Star Harvest stands as a premier example of a manufacturer that bridges the gap between artisanal detail and industrial scale. With a robust focus on OEM jewellery services, Star Harvest has integrated the entire lost wax casting workflow—from carefully crafted master models and mould-making to precision casting and meticulous finishing—supported, when appropriate, by digital tools such as 3D CAD printing.

Star Harvest understands that for medium to large-scale brands, consistency is key. By utilizing advanced vacuum casting systems and rigorous quality control protocols, they minimize common defects like porosity, ensuring that every piece meets the exacting standards required by global brands. Whether the requirement is for high-volume collections or intricate fine jewellery, Star Harvest offers the technical infrastructure and supply chain transparency necessary to support sustainable brand growth.

Conclusion

Lost-wax jewellery casting is not just a technical procedure—it is the foundation that enables true customisation and finely detailed craftsmanship at scale. When supported by the right workflow and selective digital integration, the process allows brands to reproduce intricate textures, organic forms, and bespoke design elements with consistency. For UK brands seeking to stand out through individuality and refined detail, the real advantage lies in partnering with a manufacturer who understands both the creative intent behind each piece and the precision required to realise it.

Visit Star Harvest to see how their casting expertise can transform your studio concepts into repeatable, artisan-grade jewellery ready for the modern market.