We have been focusing on brass and stainless steel jewelry craftsmanship for 20 years, accurately understanding the design concepts of global brands. Using mature mass production technology to solve quality concerns about bulk goods and leveraging efficient supply chains, our stainless steel jewelry manufacturer can quickly transform unique designs into successful custom stainless steel jewelry.

We launch innovative designs every day to help your brand stay competitive and fresh in the market. Every new product from our stainless steel jewelry factory is rigorously tested to ensure compliance with international standards and environmental requirements, making it ideal for custom stainless steel jewelry.

We launch innovative designs every day to help your brand stay competitive and fresh in the market. Every new product is rigorously tested to ensure compliance with international standards and environmental requirements.

We not only provide basic OEM production services, but also build a complete SH service system from market trend insights, flexible production to stable production capacity guarantee, making production delivery more efficient and product design more in line with market demand. Whether it is a mature e-commerce brand or a fast-growing e-commerce brand, our stainless steel jewelry manufacturer can provide fast response, differentiated technology, and zero-risk supply chain support, truly achieving seamless connection from “design concept to product shelf,” while supporting custom stainless steel jewelry production.

Since 2005, we have been focusing on the production of brass jewelry manufacturing and stainless steel jewelry with mature technology and stable quality.

A minimum order of 200 pieces/item quickly responds to the needs of emerging brands and reduces inventory pressure, ideal for launching custom brass jewelry.

From design to sample, the average cycle is 7-15 days, which can shorten the development cycle and speed up the product launch.

From material procurement, production and processing to quality inspection and packaging, all are completed in our own brass jewelry factory to ensure stable delivery and quality.

We provide special electroplating, laser engraving, texture patterns and other self- developed technologies to help your brand establish exclusive product tonality.

Unique SH-P quality system and multi- step QC process ensure that each product meets your needs and reduces quality issues.

Sufficient production capacity allows timely stocking regardless of peak or off-peak seasons, helping you respond efficiently to changes in market demand.

We provide professional and flexible stainless steel jewelry manufacturer and OEM customization services, from raw materials to finished products, to ensure that each product meets your market positioning and brand tone. Whether it is a new design and development or an existing product optimization, we can create custom stainless steel jewelry with stable quality and reliable delivery according to your needs.

We specialize in stainless steel jewelry manufacturer and OEM/ODM customized production of brass and stainless steel (316L/304) jewelry, providing full-process customization of material hardness, thickness, surface treatment (polished/brushed/vintage/PVD gold-plated rose gold, etc.), and can quickly produce samples within 7-10 days to verify the feasibility of the design. At the same time, our stainless steel jewelry factory supports environmentally friendly coatings and low-sensitivity alloys, ensuring every piece of custom stainless steel jewelry meets global market standards.

With over 20 years of jewelry customization experience, and as a stainless steel jewelry manufacturer, we have developed more than 12,000 brass and stainless steel styles. Industrial-grade 3D scanners (±0.03mm accuracy) achieve millimeter-level restoration of design drafts, maintaining material hardness and color consistency from samples to bulk goods. Each product design supports NDA signing, sample packaging material development, and export compliance certification hosting. You only need to focus on design, while the execution of the production supply chain is supported by our custom stainless steel jewelry capability and stainless steel jewelry factory resources.

SH provides a variety of gemstone options, including natural gemstones directly mined from mines/laboratory-grown diamonds/artificial gemstones. You can freely choose according to your needs. All gemstones are certified with IGI/GIA dual certificates, and support customized solutions from special-shaped cutting to micro-setting processes, as well as complying with RJC system metal traceability standards. 48-hour ultra-fast proofing reduces development risks.

We can provide various electroplating layers, such as 10k, 14k, 18k, and 22k according to your needs, and support various electroplating color options such as single color, multi-color, gradient, etc. As a stainless steel jewelry manufacturer, SH-type vacuum coating technology is used to achieve electroplating color retention > 3 years wear test cycle (in line with EN 12472 artificial sweat test). The special color plating solution library supports accurate restoration of metal color numbers, and the electroplating solution ingredients can be traced. At the same time, it meets RoHS/REACH heavy metal migration control requirements, ensuring that products from a trusted stainless steel jewelry factory are of high quality. As reliable stainless steel jewelry suppliers, the best results are guaranteed through stainless steel jewelry maker expertise.

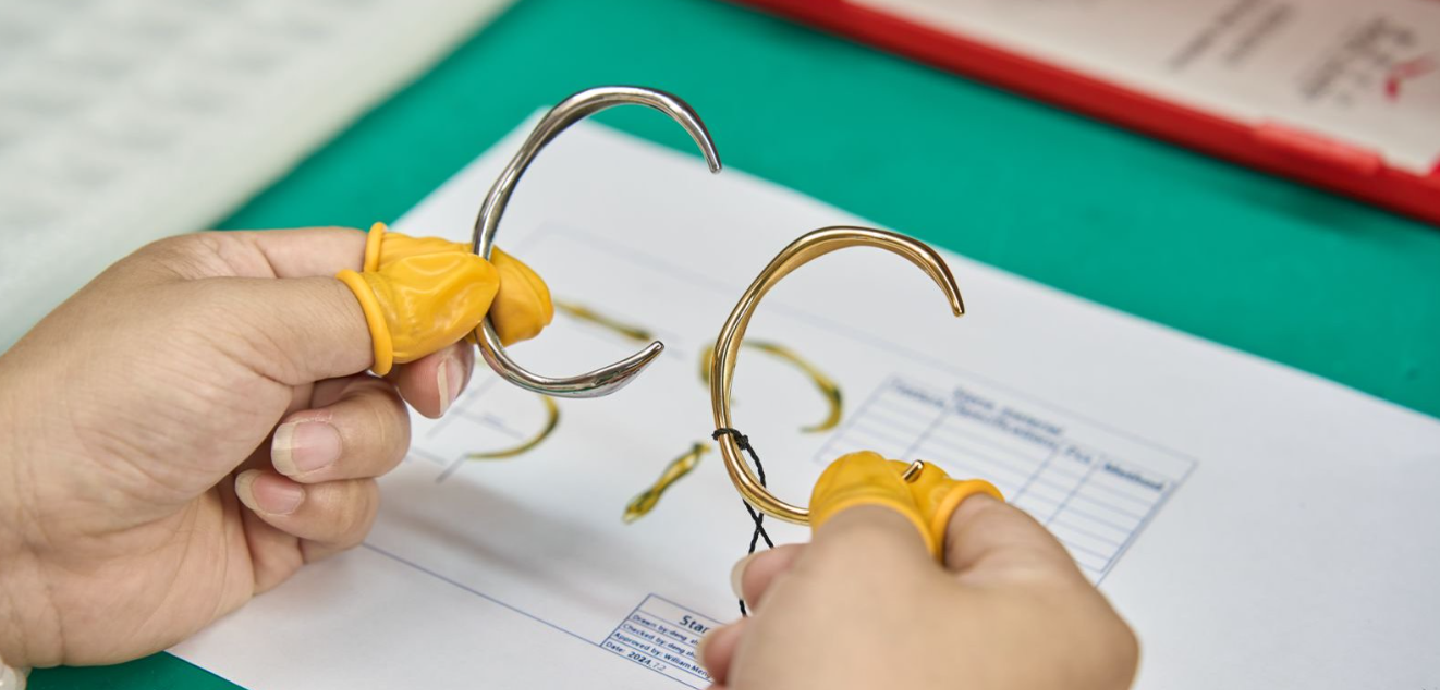

Supports the design and development of 127+ jewelry accessories including chains, clasps, and link rings. Years of fine processing and manufacturing experience ensure lead-free solder joints and ASTM F2923 tensile strength standards. As a brass jewelry factory with established brass jewelry manufacturing capability, and compatible with custom brass jewelry production, the use of German precision cutting equipment allows accessory processing tolerances below 0.1mm. One-stop customization covers logo stamping and packaging materials, and supports a variety of materials such as brass and stainless steel, in compliance with Annex XVII of REACH regulations.

Over 20,000+ brass and stainless steel basic style libraries, you can choose any modification, including logo stamping, size adjustment, accessory replacement, font elements, pattern customization and other requirements. All products meet environmental certification and can provide corresponding quality inspection reports, and comply with ISO 9001 quality system and Amazon FBA packaging specifications, helping you to quickly distribute products with minimal development costs.

This position contains the description text of the module, which can be retained or deletedThis position contains the description text of the module,

Copper and stainless steel raw materials entering the stainless steel jewelry factory must be inspected. The inspection content includes verification of component reports, surface finish, and hardness to ensure that the metal raw materials comply with ROHS & REACH standards, controlling quality from the source and guaranteeing that every piece of custom stainless steel jewelry produced by our stainless steel jewelry manufacturer meets the highest standards.

3D scanning compares the design drawings to check the wax model size error (within ±0.1mm), hollow details, and overall proportions to prevent later rework caused by mold deviation.

After casting, the embryos are 100% inspected for trachoma, bubbles, and deformation, and the internal structure is inspected by X-ray to ensure there are no invisible defects.

Double inspection by manual and machine ensures that the welding points are firm, the lines are smooth and free of burrs, and the surface flatness meets the standards (sampling rate 30%, 100% for high-risk models).

Check for residual stains after ultrasonic cleaning, test surface adhesion after pickling, and compare the color plate with the opponent’s plate to avoid color difference after electroplating.

Salt spray test + abrasion test sampling, visual inspection of mirror/matte process halo uniformity, coating thickness meter detection (0.03μm accuracy), additional test of anti-fingerprint layer.

Both functionality and aesthetics are ensured – fastener opening and closing tests are conducted 500 times, stone setting firmness is tested through vibrations, scratches/discoloration are checked visually, and AQL inspection reports for each batch are kept on file.

Check order requirements (lettering, accessories, packaging), use metal detectors to check for residual debris, scan anti-theft labels/environmental labels one by one, and conduct a second random inspection before sealing the box