Electroplating inspection

Randomly select coating samples, use X-ray thickness gauge to detect coating uniformity (≥0.08μm), and perform salt spray test for 48 hours to verify anti-discoloration performance and avoid the risk of oxidation and deplating.

Electroplating inspection

Randomly select coating samples, use X-ray thickness gauge to detect coating uniformity (≥0.08μm), and perform salt spray test for 48 hours to verify anti-discoloration performance and avoid the risk of oxidation and deplating.

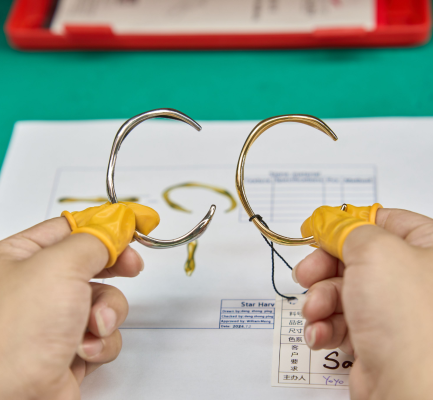

Metal blank inspection

Five pieces are randomly inspected every hour, and key parts (such as chain link closure and weld strength) are checked using calipers and projectors to ensure that the metal blanks are free of sand holes and structural defects.

Wax embryo inspection

3D scanning compares the design drawings, detects dimensional errors (±0.15mm tolerance), removes problematic parts such as bubbles and deformation, and ensures that the wax model 100% meets the mold opening standards.