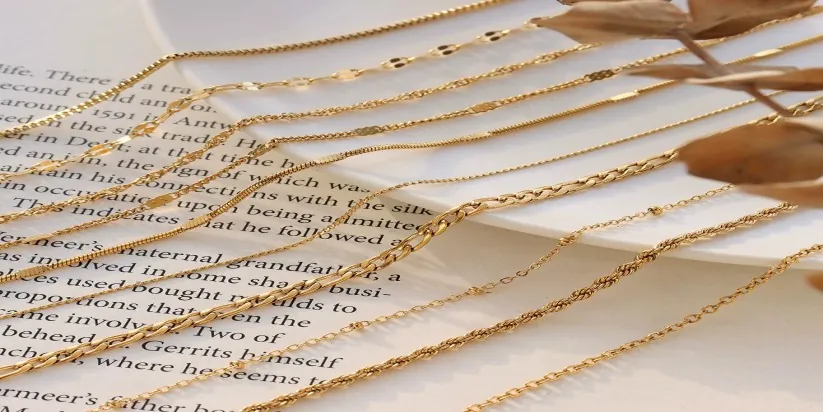

For jewelry brands, the question isn’t just if gold plating jewelry is durable, but rather how durable it is—a factor entirely dependent on the quality of the manufacturing process. Gold plating, by its nature, is a thin layer of gold applied to a base metal. While it offers the luxurious look of solid gold at an accessible price point, its longevity is a variable that distinguishes professional-grade pieces from mass-market fashion jewelry.

The durability of gold plating is determined by three critical factors: the thickness of the gold layer, the quality of the base metal, and the precision of the gold plating jewelry service.

The Measure of Quality: Micron Thickness

The single most important indicator of durability in professional jewelry manufacturing is the gold layer’s thickness, measured in microns (μm).

Flash Plating (<0.175μm): The entry-level standard, often revealing the base metal within months. Suitable primarily for fast-fashion costume jewelry.

Standard Plating (0.5−1.0μm): Offers moderate resistance to wear, typically lasting 1 to 2 years with proper care. This is a common choice for mid-range fashion jewelry brands.

Heavy Plating (≥2.5μm): The premium standard for durability. While often associated with certain precious metal bases, this thickness on high-grade stainless steel provides exceptional resistance to abrasion and corrosion, often lasting 3 to 5+ years, making it ideal for high-use items like rings.

The Manufacturer’s Edge: Star Harvest’s Durability Standards

A premier jewelry factory like Star Harvest understands that durability is built from the ground up, specifically catering to the needs of mid-to-large scale brands and rapidly growing e-commerce labels. Our gold plating jewelry service integrates advanced industrial technologies and rigorous quality control to significantly extend the lifespan of every finish.

Through these strict production standards, Star Harvest ensures that our gold plating jewelry achieves the color retention and wear resistance necessary for professional brands to build long-term customer satisfaction and market trust.

Maximizing the Lifespan of Gold Plating

While the factory’s production quality is paramount, end-user care plays a vital role in maintaining the professional finish. For the best durability, clients should advise their customers to:

Avoid Friction: Remove jewelry during tasks involving frequent surface contact (e.g., manual labor or intense exercise).

Limit Chemical Exposure: Keep pieces away from harsh chemicals found in perfumes, chlorine, and lotions, as these can accelerate the breakdown of the gold layer.

Store Properly: As a professional jewelry factory, we recommend storing pieces in soft pouches or separate compartments to prevent scratches and maintain the integrity of the plating.

Ultimately, gold plating jewelry is durable when it is produced with high-micron thickness and professional-grade methods. Choosing a specialized gold plating jewelry service like Star Harvest that prioritizes process and materials is the single best investment a brand can make in product quality and customer loyalty.